Ultrasonic flow meters

The term ‘ultrasonic’ refers to the signals (usually are short bursts of sine waves) whose frequency is above the range audible to human hearing which is 20 to 20000 Hz.

Principle

The ultrasonic flow meter operates on the principle that the velocity of sound in a fluid in motion is the resultant of the velocity of sound in the fluid at rest plus or minus the velocity of the fluid itself.

Types of Ultrasonic Flow Meters

- Transit time flow meters

- Doppler Flow meter.

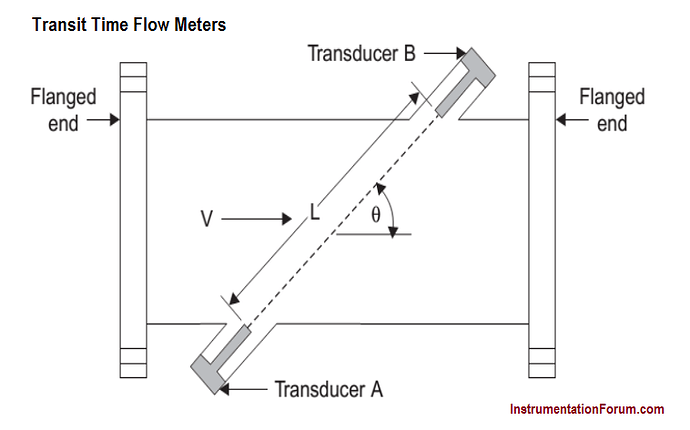

Transit Time Flow Meters

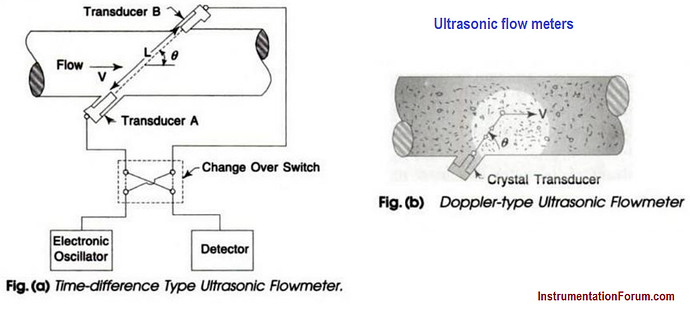

As the name implies these devices measure flow by measuring the time taken by an ultrasonic energy pulse to traverse a pipe section, both with and against the flow of the liquid within the pipe. Fig. 1 shows a transit time flow meter.

The time (tAB) for the ultrasonic energy to go from transducer A to transducer B is given by the expression:

tAB = L/(C + V. cos θ)

The time (tBA) to go from B to A is given by

tBA = L/(C – V.cos θ)

where C is the speed of sound in the fluid, L is the acoustic path length in the fluid,

θ is the angle of the path with respect to the pipe axis.

By combining and simplifying, it can be shown that for V << C :

∆t = tBA – tAB = 2.L.V. cos θ/C

It can be shown that :

V = C.∆t/2 L cos θ

Since the cross sectional area of the pipe section or ‘spool pipe’ is known, the product of area and velocity will yield the volumetric flow rate.

Doppler Flow Meters

This type of flow meter is based on Doppler principle.

The transmitter of a Doppler flow meter projects an ultrasonic beam at a frequency of about 0.5 MHz into the flowing stream and deflects the reflected frequency.

The difference between transmitted and reflected velocities is called the ‘beat frequency’ and is related to the velocity of the reflecting surfaces (solid particles and gas bubbles) in the process stream.

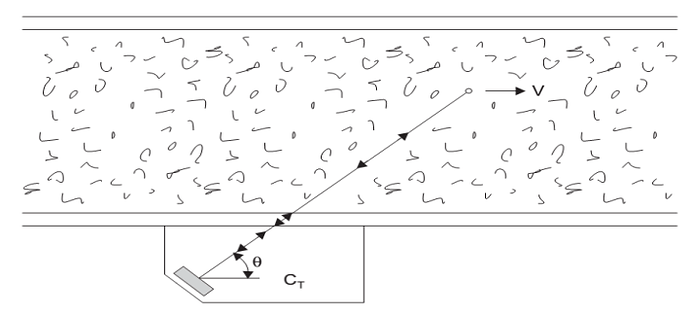

Principle of Operation

As shown in Fig.3, an ultrasonic wave is projected at an angle through the pipe wall into the liquid by a transmitting crystal in a transducer mounted outside the pipe.

Part of the energy is reflected by bubbles or particles in the liquid and is returned through the pipe wall to a receiving crystal.

If the reflectors are travelling at the fluid velocity, the frequency of the reflected wave is shifted according to the Doppler principle, in proportion to the flow velocity.

Combining Snell’s law and Doppler equation, the flow velocity can be determined as follows if V << C.

V = ∆f.Ct /(2.fo .cos θ) = ∆f.K

where ∆f = Difference between transmitted and received frequency, fo= frequency of transmission, Ct = Velocity of sound in the transducer. θ = angle of the transmitter and receiver crystal with respect to the pipe axis,

As shown in equation, velocity is a linear function of ∆f. Since the inside diameter (ID) of the pipe is known, volumetric flow rate can be measured as a function of V and square of ID

Advantages:

-

Ultrasonic meters are made up of no moving parts.

-

They experience no pressure loss.

-

They endow with maintenance-free operation. It is a key advantage as compared to conventional mechanical meters such as positive displacement meters, turbines etc.

-

Furthermore, Ultrasonic flowmeters are consistently more accurate and reliable than a lot of other metering systems.

-

With the emergence of 3-beam ultrasonic, all other flowmeters like mass, vortex, positive displacement and turbine flowmeters which are used to measure non-conductive fluids, have been successfully replaced by ultrasonic meters.

Disadvantages:

-

Still problematic for liquid and gas measurements

-

Sound beam must traverse a representative cross section, therefore flow profile dependent. Long inlet and outlet sections required

-

Errors due to deposits

-

Transit time meters require clean liquids

-

Doppler meters only for slight contamination or few gas bubbles

-

Doppler meters affected by sound velocity changes due to temperature, density and concentration

-

Unsuitable for heavily contaminated liquids

-

Gas bubbles cause errors

Applications

-

Ultrasonic flowmeters are perfect for wastewater applications or any other dirty liquid which is conductive or water based.

-

Ultrasonic flowmeters normally does not work with distilled water or drinking water. Aerations would be needed in the clean liquid applications.

-

Ultrasonic flowmeters are also best suited for applications where low pressure drop, chemical compatibility, and low maintenance are involved.