The program relay will recycle automatically each time the operating control closes, or after a power failure. It will lockout following a safety shutdown caused by failure to ignite the pilot, or the main flame, or by loss of flame. Lockout will also occur if flame or flame simulating condition occurs during the pre-purge period.

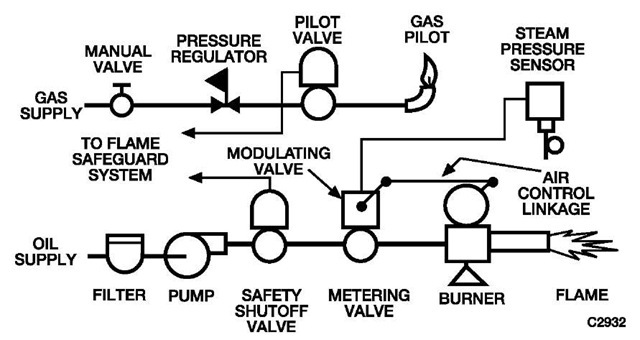

Combustion control for rotary oil burner/gas furnace.

The control will prevent startup or ignition if limit circuit controls or fuel valve interlocks are open. The control will lock out upon any abnormal condition affecting air supervisory controls wired in the running interlock circuit.

WARNING!

The lockout switch must be manually reset following a safety shutdown. The cause for loss of flame or any unusual condition should be investigated and corrected before attempting to re-start. Failure to follow these instructions could result in serious personal injury or death!

The lockout switch must be manually reset following a safety shutdown. The cause for loss of flame or any unusual condition should be investigated and corrected before attempting to re-start. Failure to follow these instructions could result in serious personal injury or death!

- ‘’‘NO PILOT FLAME’‘‘The pilot flame must be ignited and proven within a 10-second period after the Troubleshooting and ignition cycle begins. If not proven within this period, the main fuel valve circuit will not be powered and the fuel valve(s) will not be energized. The ignition circuit is immediately de-energized and the pilot valve closes, the reset switch lights and lockout occurs immediately.The blower motor will continue to operate. The flame failure light and the alarm bell (optional) are energized 10 seconds later.The blower motor will be de-energized.’’‘The lockout switch must be manually reset before operation can be resumed.’‘’

- ‘’‘PILOT BUT NO MAIN FLAME’‘‘When the pilot flame is proven, the main fuel valve circuit is energized. Depending upon the length of the trial-for-ignition period, the pilot flame will be extinguished 10 or 15 seconds later. The flame detecting circuit will respond to de-energize the main fuel valve circuit within 2 to 4 seconds to stop the flow of fuel. The reset switch lights and lockout occurs immediately. The blower motor will continue to operate.The flame failure light and alarm bell (optional) are energized 10 seconds later.The blower motor will be de-energized. ‘’‘The lockout switch must be manually reset before operation can be resumed.’’’

- ‘’‘LOSS OF FLAME’‘‘If a flame outage occurs during normal operation and/or the flame is no longer sensed by the detector, the flame relay will trip within 2 to 4 seconds to de-energize the fuel valve circuit and shut off the fuel flow. The reset switch lights and lockout occurs immediately. The blower motor continues operation. The flame failure light and alarm bell (optional) are energized 10 seconds later.The blower motor will be de-energized. ‘’‘The lockout switch must be manually reset before operation can be resumed.’’’

If the burner will not start, or upon a safety lockout, the trouble shooting section in the operating manual and the technical bulletin should be referred to for assistance in pinpointing problems that may not be readily apparent.

The program relay has the capability to self-diagnose and to display a code or message that indicates the failure condition. Refer to the control bulletin for specifics and suggested remedies. Familiarity with the program relay and other controls in the system can be obtained by studying the contents of the manual and this bulletin.

Knowledge of the system and its controls will make troubleshooting much easier. Costly down time or delays can be prevented by systematic checks of the actual operation against the normal sequence to determine the stage at which performance deviates from normal. Following a routine may possibly eliminate overlooking an obvious condition, often one that is relatively simple to correct.

Remember, a safety device, for the most part, is doing its job when it shuts down or refuses to operate. Never attempt to circumvent any of the safety features.

Preventive maintenance and scheduled inspection of all components should be followed. Periodic checking of the relay is recommended to see that a safety lockout will occur under conditions of failure to ignite either pilot or main flame,

Safety shutdown (lockout) occurs if:

|PERIOD|LOCKOUT OCCURS IF:

- Standby Period

- Incorrect fuel selection input

- Pre-ignition interlock open

- Flame signal is present continuous for more than 40 seconds

- Pilot/ignition terminal energized

- Main oil valve terminal energized

- Main gas valve terminal energized

- Internal system fault

- Damper motor fault

- Pre-Purge Period

- Incorrect fuel selection input

- Pre-ignition interlock open

- Lockout interlock open (after 10 seconds into the pre-purge period)

- Flame present, after 10 seconds into the pre-purge period.

- Oil pressure fault:

-

833-2417 Program Module; lock out if pressure is not within limit values, after 10 seconds into the prepurge period.

-

833-2418 Program Module; lock out if oil pressure is not within limit values.

- Oil temperature fault:

-

833-2417 Program Module; lock out if high oil temperature limit exceeded, after 10 seconds into the ignition period.

-

833-2418 Program Module; lock out if oil temperature is not within limit values, after 10 seconds into the pre-purge period.

- Damper motor fault

- Pilot valve/ignition terminal energized

- Main oil valve terminal energized

- Main gas valve terminal energized

- Internal system fault

- Faulty gas pressure sensor

- Pilot Flame Establishing Period

- Incorrect fuel selection input

- Pre-ignition interlock open or shorted

- Lockout interlock open

- No flame established

- Gas pressure limit or sensor fault

- Oil pressure limit fault, heavy oil only

- Oil temperature limit fault

- Damper motor fault

- Pilot valve or ignition terminal not energized

- Main oil valve energized

- Main gas valve energized

- Internal system fault

- Main Flame Establishing Period

- Incorrect fuel selection input

- Lockout interlock open

- No flame present

- Gas pressure limit fault

- Oil pressure limit fault, heavy oil only

- Oil temperature limit fault

- Atomizing air pressure switch open, oil selected fuel

- Damper motor fault

- Pilot/ignition transformer terminal de-energized

- Main oil valve de-energized, oil selected fuel

- Main gas valve de-energized, gas selected fuel

- Internal system fault

- Run Period

- Incorrect fuel select input.

- No flame present.

- Lockout interlocks open.

- Gas pressure limit fault.

- Oil pressure limit fault, heavy oil only.

- Oil temperature limit fault.

- Atomizing air de-energized, oil selected fuel.

- Damper motor fault.

- Pilot/ignition terminal energized.

- Main valve terminal de-energized, selected fuel.

- Main valve terminal energized, main valve of fuel series not selected.

- Internal system fault.|

- Post-purge Period

- Pre-ignition interlock open after five seconds.

- Atomizing air terminal de-energized; oil selected fuel

- Pilot/ignition terminal energized

- Main oil valve terminal energized

- Main gas valve terminal energized

- Internal system fault

- Damper motor fault|