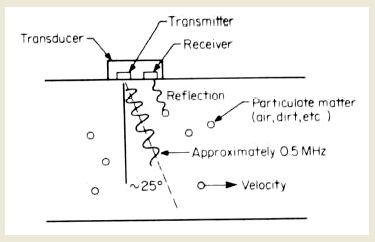

Doppler ultrasonic flow meter operate on the doppler effect. In Doppler effect, One transducer transmits an ultrasonic beam of 0.5Mhz into the flow stream.

Liquid flowing through the pipe must contain sonically reflected materials such as solid particles or air bubbles. the movement of these materials alters the frequency of the wave reflected onto a second receiving transducer.

The frequency shift is linearly proportional to the rate of flow of materials flowing in the pipe.

Advantages and Disadvantages of Doppler Flow Meter

The main advantage of doppler flow meter is its non-intrusive design.

An acoustic-coupling compound is used on the surface of the pipe and the sensors are simply held in place to take a measurement or, for a more permanent installation, they are strapped around the pipe.

Some manufacturers offer a special clamp-on probe which allows connection to smaller pipe sizes.

Advantages Of Doppler Flow Meter:

Other advantages include:

-

Easy installation and removal.

-

No process downtime during installation.

-

No moving parts to wear out.

-

No process contamination.

-

Works well with dirty or corrosive fluids.

-

No leakage potential.

-

Insensitive to liquid temperature, viscosity, density or pressure variations.

Disadvantages Of Doppler Flow Meter:

The main disadvantage of the doppler flow meter is the fact that the liquid stream must have particulates, bubbles, or other types of solids in order to reflect the ultrasonic signal. This means that the doppler flow meter is not a good choice for the water and very clean fluids.

The another disadvantage is that the accuracy can depend on particle-size distribution and concentration and also on any relative velocity that may exist between the particulates and the fluid. if there are not enough particulates available, the repeatability will degrade.

The other potential problem of this technology is that it can have trouble operating at very low flow velocities.

Applications Of Doppler Flow Meter:

Being an non-intrusive, Doppler flow meters have a wide variety of applications.

Some of them include:

-

Influent and effluent water flow.

-

Digester feed control.

-

Waste water.

-

Crude oil flow.

-

Mining slurries.

-

Acids.

-

Liquified gases.