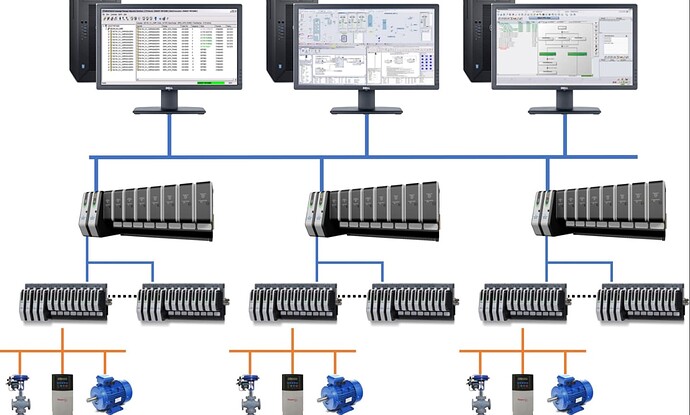

Because a system can be broken down into subsections that communicate freely with one another, DCS makes the design, implementation and maintenance of complex control strategies easier.

Although simpler design and (to some extent) implementation appear to benefit primarily the DCS supplier, the user also benefits — from shorter leadtimes, simpler systems, improved reliability, reduced downtime, reduced installation costs due to wire savings, and greater flexibility to make future enhancements.

Ideally, the DCS will use common hardware throughout. This simplifies the design, since the programming methods and documentation become independent of the subsection that is being designed

If the DCS is well designed, the engineer has a great deal of freedom to construct the system in a logical manner, taking into consideration the effects of single-point failures on the operation of the process.

Unlike control systems based on other strategies, the DCS can continue to operate in a semiautomatic mode when one control section fails. The process can be kept operational while the failed section is repaired, although the process may operate at less than peak efficiency.