The Bently Nevada Condition Monitoring System used to monitor vibration and temperature of large rotating equipment in oil and gas industries.

Proximitor or Seismic Monitor

The Proximitor or Seismic Monitor is a 4-channel monitor that accepts input from proximity and seismic transducers, conditions the signal to make various vibration and position measurements, and compares the conditioned signals with user-programmable alarms.

Each channel of the 3500/42M can be programmed using the 3500 Rack Configuration Software to perform any of the following functions:

•radial vibration

•thrust position and differential expansion

•acceleration and velocity

•acceleration 2 and velocity 2

•slow speed eccentricity

•shaft absolute measurements

•Circular Acceptance Regions (CAR)

•REBAM

•provides 4 to 20 ma recorder output.

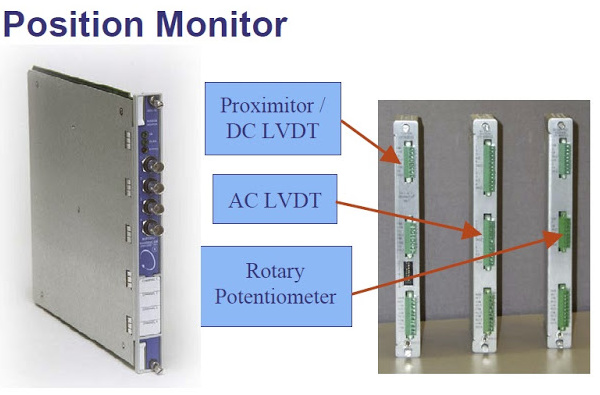

Position Monitor:

The 3500/45 Position Monitor is a four channel monitor that accepts input from proximity transducers, linear variable differential transformers (DC & AC LVDTs), and rotary potentiometers and uses this input to drive alarms.

The 3500/45 can be programmed using the 3500 Rack Configuration Software to perform any of the following functions:

•thrust position and differential expansion

•standard and nonstandard single ramp differential expansion

•dual ramp differential expansion

•complementary differential expansion

•case expansion

•valve position

Monitoring System Rack Interface Modules (RIM):

The Rack Interface Module (RIM) is the primary interface into the 3500 rack. 3500 Monitoring System has two versions of the RIM, the 3500/20 RIM and the 3500/22M TDI. Both of these Rack Interface Modules support a Bently Nevada proprietary protocol used to configure the rack and retrieve machinery information.

The 3500/20 RIM provides the connections needed to support external Bently Nevada Communications Processors such as the Transient Data Interface External (TDIX) and the Dynamic Data Interface External (DDIX).

The 3500/22M TDI performs all of the functions of a Rack Interface Module and has a communications processor called the Transient Data Interface embedded into the module.

Although the RIM does provide certain functions common to the entire rack, the RIM is not part of the critical monitoring path. The RIM’s operation (or nonoperation) has no effect on the proper, normal operation of the overall monitoring system.

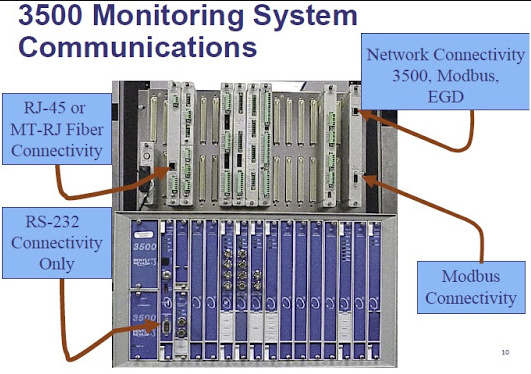

3500 Monitoring System Communication:

The 3500 Monitoring System allows communication through several interfaces, and can allow communication with more than one of these at a time. Examples of this connectivity include:

• temporary or permanent RS-232 or RS-422 connection to the back of the rack at the I/O interface (the RS-232 connection is only for the RIM I/O)

• temporary RS-232 connection to the front of the 3500/20 Rack Interface Module (RIM) or 3500/22M TDI (Transient Data Interface)

• network connection directly to 3500/22M TDI I/O or to the 3500/20 RIM through the communication gateway module

• serial and/or network connection to other Modicon Modbus or EGD (Ethernet Global Data) Gateway devices through the communication gateway module

• dynamic and static connectivity to the TDXnet™ Communications Processor for data collection by Data Manager® 2000 software or System 1™ Data Acquisition software

• MT-RJ fiber or RJ-45 twisted-pair Ethernet connection to the 3500/22M TDI for data collection by 3500 software or System 1™ Data Acquisition software

3500 Communication Processors:

A communication processor collects and stores information from a monitoring system and communicates this information to a host computer and/or digital control system (DCS). Communication Processors let you collect and process waveform records that can be used for advanced machinery diagnosis. 3500 Monitoring Systems commonly use two communication processors, the TDXnet and the 3500/22M TDI.

The TDXnet communication processor is an external device that is connected to the 3500 rack using the connectors on the Data Manager I/O module. Racks that use a TDXnet must have a 3500/20 RIM and a Data Manager I/O installed in the rack.

The Transient Data Interface (TDI) communication processor is imbedded into the 3500/22M TDI. 3500 racks that use the TDI communication processor require that the monitors installed in the rack be “M enabled”. The rack must also include a backplane that contains an additional third connector for each monitor.

Redundant Power Supplies:

There are several redundant conditions designed into the 3500 monitoring system. One of these redundant conditions is the use of two power supplies. Both can be High or Low DC voltage, High or Low AC voltage or a mixture of two out of the four choices. Either power supply can take over if the other one fails without any monitoring system interruption.