The bubbler tube system uses a small, regulated airflow that constantly bubbles into the liquid to measure its level.

Because the airflow is small, the system produces a backpressure equal to the static head of the liquid.

A conventional pressure gauge or transmitter measures this back pressure as the height of an equivalent water column.

Bubbler Level Measurement System

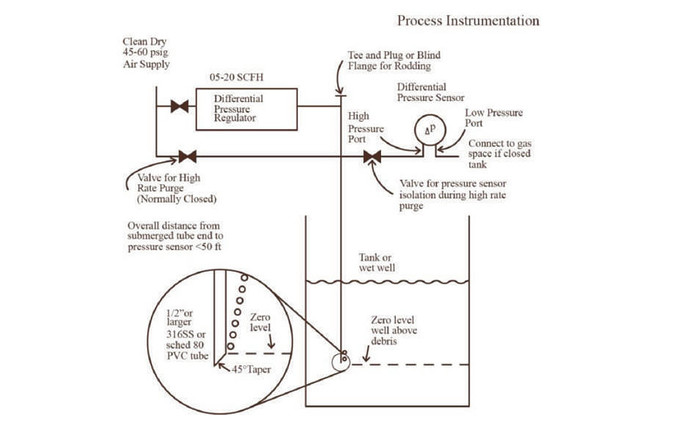

A schematic of bubbler tube system is shown in Figure.

Source: WEF,2008

Figure:Schematic of bubbler-level system

Corrections are required when the liquid’s specific gravity differs significantly from water. Because air is constantly bubbling out of the bubbler tube, the system is typically self-purging.

Valves may be arranged to isolate the pressure-measuring device while providing high purge flow through the tube for preventive maintenance blow-down if fouling occurs.

Stilling wells are often used to protect the bubbler tube from turbulence and damage.

To protect pneumatic instruments and regulators, operators should clean the air supply of excessive moisture and oils.

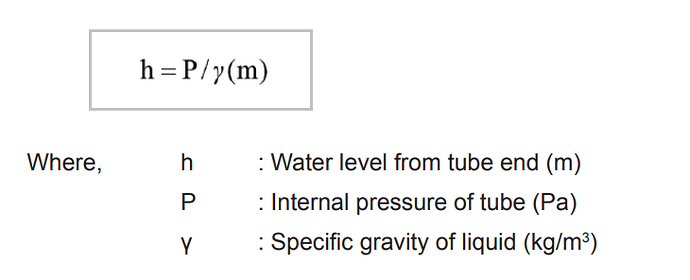

When bubbles are discharged into the liquid from the front end of pipe, the pressure within the pipe becomes equal to the static pressure of liquid at the front end of the pipe. This pressure is proportional to the liquid height h.

The calculation is expressed as given below:

Precautions for O&M are as given below.

The bubble type liquid level gauge does not have moving parts or mechanisms, so it has comparatively high accuracy. Moreover, it is suited to level gauges for corrosive liquids.

However, daily maintenance of air sources such as compressor, purging set and air piping is very important.