LNG is a non-toxic liquid which forms when natural gas is cooled to -162ºC (-260ºF). The cooling process shrinks the volume of the gas, making it easier and safer to store and ship. In its liquid state, LNG cannot ignite.

When LNG reaches its destination, it is turned back into a gas at regasification plants. It is then piped to homes, businesses and industries where it is burnt for heat or to generate electricity.

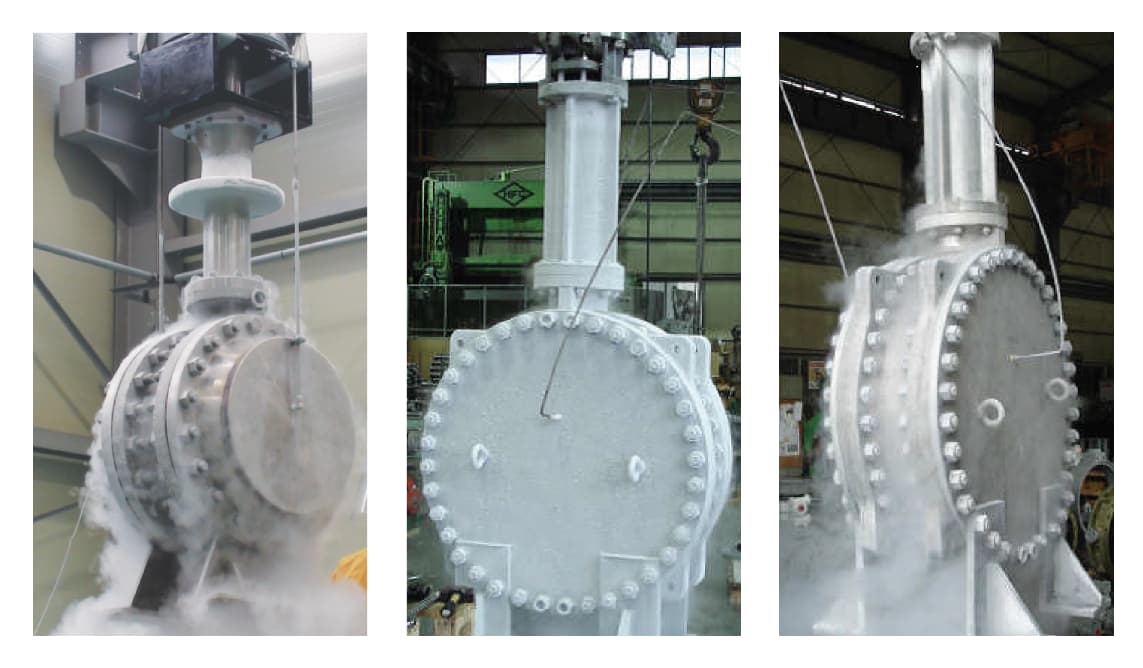

Butterfly valve in Cryogenic LNG Application

LNG Triple Eccentric Metal Seated Cryogenic butterfly valves are suitable for bi-directional flow and bubble tight shut-off at full rated pressure with extended bonnet according to BS 6364, Direct Mount ISO table, adjustable gland packing, one-piece blow-out proof stem, pinned disc and metal seat.

The materials used throughout are austenite stainless steel which maintains its strength at low temperatures. The sealing system is metal seated providing bi-directional bubble tight shut-off.

An extended bonnet design is used to create an insulation gas column between the stem packing and the cold fluid. This design prevents hardening and shrinking of the packing.

Butt-welding ends have a side entry maintenance system that allows replacement of the sealing ring without removing the valves from the pipeline.

Credits: frenstarvalves