A butterfly valve is a valve that can be used for isolating or regulating flow. The closing mechanism takes the form of a disk.

Operation is similar to that of a ball valve, which allows for quick shut off.

Butterfly valves are generally favored because they are lower in cost than other valve designs as well as being lighter in weight, meaning less support is required.

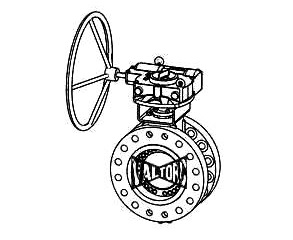

Butterfly Valve

The disc is positioned in the center of the pipe; passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow.

Unlike a ball valve, the disc is always present within the flow; therefore a pressure drop is always induced in the flow, regardless of valve position.

A butterfly valve is from a family of valves called quarter-turn valves. The butterfly is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway.

When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

There are different kinds of butterfly valves, each adapted for different pressures and different usages. The resilient butterfly valve, which uses the flexibility of rubber, has the lowest pressure rating.

The high performance butterfly valve, used in slightly higher-pressure systems, features a slight offset in the way the disc is positioned, which increases the valve’s sealing ability and decreases its tendency to wear.

The valve best suited for high-pressure systems is the triple offset butterfly valve, which uses a metal seat, and is therefore able to withstand a greater amount of pressure.

Types

- Concentric butterfly valves – this type of valve has a resilient rubber seat with a metal disc.

- Doubly-eccentric butterfly valves (high-performance butterfly valves or double-offset butterfly valves) – different type of materials is used for seat and disc.

- Triply-eccentric butterfly valves (triple-offset butterfly valves) – the seats are either laminated or solid metal seat design.

More info -