The vibration in rotating machinery is caused by many reasons like unbalance, misalignment, loose foundation, mechanical looseness, bearing damage etc.

Vibration monitoring is the most common, versatile and powerful condition monitoring technique adopted in rotating machinery to identify problem areas.

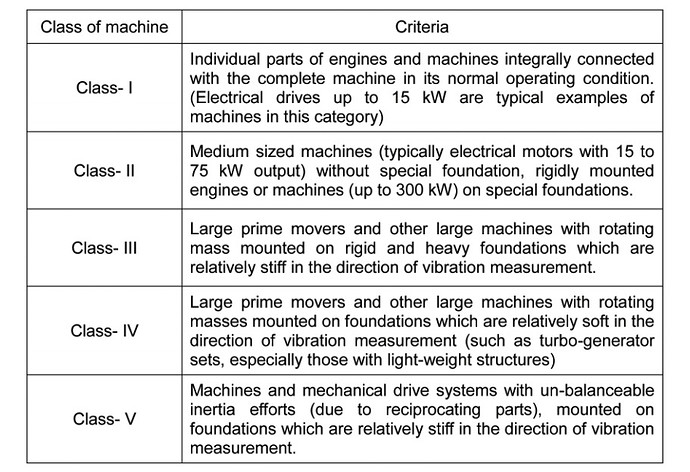

The severity of the vibration is specified by IS 2372, which is measured with reference to class of machine. The criteria for class of machine are given in Table 1 overleaf.

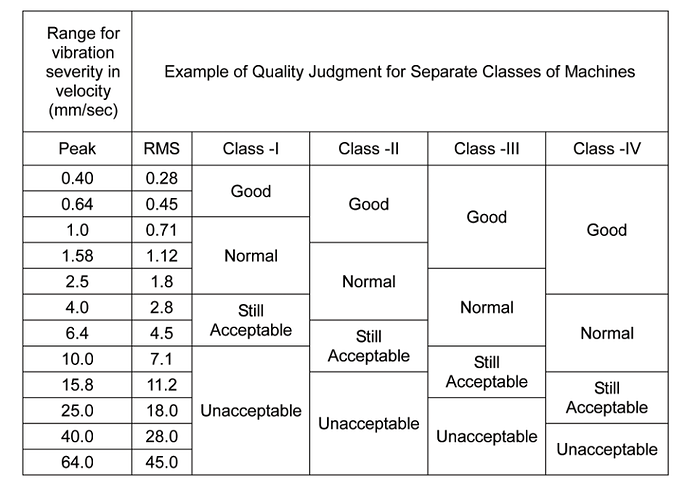

For the above class of machine, the vibration severity can be judged by the guidelines shown in Table 2 overleaf.

Table 1 Criteria for class of machine

Table 2 Vibration severity chart for machine vibration limits

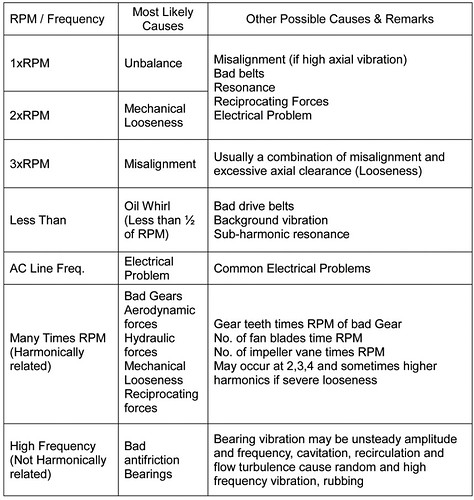

The guidelines for vibration frequencies and likely causes are mentioned in Table 3 overleaf.

Table 3 Vibration frequencies and likely causes

Vibration Analysis

If the measured vibration level is more than the acceptable level, then it calls for vibration analysis, which is a captured time waveform plotted as amplitude versus time, or data can be transformed using a Fast Fourier Transform (FFT) and expressed as amplitude versus frequency.

Any random vibration signal can be represented by a series (a Fourier series) of individual sine and cosine functions that can be summed to yield an overall vibration level.

The amplitude of this vibration signal defines the severity of the problem.

Plotting the amplitude versus the frequency (the Fourier spectrum) allows for identification of discrete frequencies contributing most to the overall vibration signal, commonly referred to as a “signature analysis” or a “frequency spectrum”, Machine looseness, misalignment, imbalance, and soft foot conditions are all fairly easily identified in the frequency spectrum generated by an analyser.

The vibration monitoring and analysis should be done periodically, typically once in 6 months for all rotating equipment.