RTDs work on the principle that the electric resistance of a metal changes due to change in its temperature.

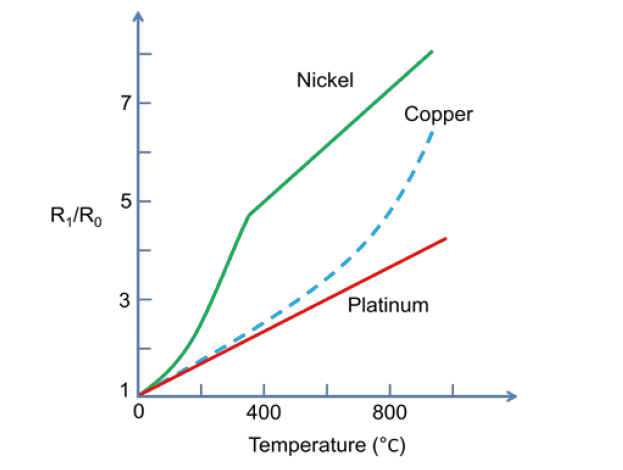

On heating up metals, their resistance increases and follows a linear relationship as shown in Figure.

The correlation is

where Rt is the resistance at temperature T (⁰C) and R0 is the temperature at 0⁰C and α is the constant for the metal termed as temperature coefficient of resistance. The sensor is usually made to have a resistance of 100 Ω at 0 °C

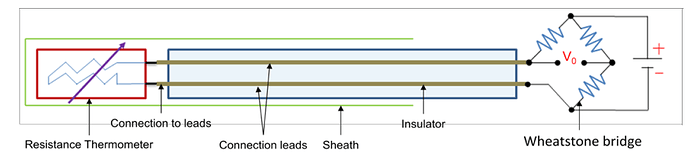

Construction of a Resistance temperature detector (RTD)

The above Figure shows the construction of a RTD. It has a resistor element connected to a Wheatstone bridge. The element and the connection leads are insulated and protected by a sheath.

A small amount of current is continuously passing though the coil. As the temperature changes the resistance of the coil changes which is detected at the Wheatstone bridge.

RTDs are used in the form of thin films, wire wound or coil. They are generally made of metals such as platinum, nickel or nickel-copper alloys. Platinum wire held by a high-temperature glass adhesive in a ceramic tube is used to measure the temperature in a metal furnace.