There are five ways to control a Variable Frequency Drive (VFD) with a Programmable Logic Controller (PLC):

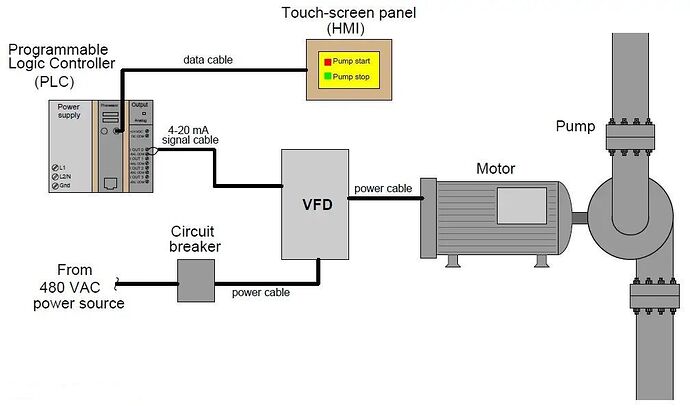

Analog Signal Control (0-10V/4-20mA)

- PLC outputs analog signal: 0-10V or 4-20mA.

- VFD receives signal: Adjusts frequency accordingly.

- Common applications: Speed control, ramping, and modulation.

Digital Signal Control (Discrete Inputs)

- PLC sends digital signals: Start/Stop, Forward/Reverse, etc.

- VFD receives signals: Executes corresponding actions.

- Common applications: Simple on/off control, direction control.

Modbus Communication

- PLC and VFD communicate: Via Modbus RTU/TCP protocol.

- PLC sends commands: Frequency setpoints, start/stop, monitoring.

- VFD responds*: Confirms receipt, executes commands.

- Common applications: Advanced control, monitoring, and diagnostics.

BACnet/IP or EtherNet/IP Communication

- PLC and VFD communicate: Via BACnet/IP or EtherNet/IP protocol.

- PLC sends commands: Frequency setpoints, start/stop, monitoring.

- VFD responds: Confirms receipt, executes commands.

- Common applications: Building automation, industrial control.

PROFIBUS or DeviceNet Communication

- PLC and VFD communicate: Via PROFIBUS or DeviceNet protocol.

- PLC sends commands: Frequency setpoints, start/stop, monitoring.

- VFD responds: Confirms receipt, executes commands.

- Common applications: Industrial automation, process control.

Additional Considerations

- Ensure compatibility: Verify PLC and VFD compatibility.

- Configure communication: Set up communication protocols.

- Program PLC logic: Develop control logic.

- Test and commission: Verify proper operation.

Popular PLC and VFD combinations

- Allen-Bradley PLC with Rockwell Automation VFD

- Siemens PLC with Siemens VFD

- Mitsubishi PLC with Mitsubishi VFD

- Schneider Electric PLC with Schneider Electric VFD

- Omron PLC with Omron VFD