The diaphragm bulb system operates on the principle that air sealed between the dry side of the diaphragm (in the capillary tube) and the receiver compresses or expands with the movement of the diaphragm.

A change in the static head of the liquid being measured moves the diaphragm, so the pressure of the trapped air is the same as the head pressure.

Temperature changes because of sunlight or heat build-up, particularly along the capillary tube, can cause measurement errors as a result of expansion of the trapped air.

To reduce the effect of temperature, the capillary can be filled with a fluid unaffected by operating temperature; however, this often affects the measurement response time.

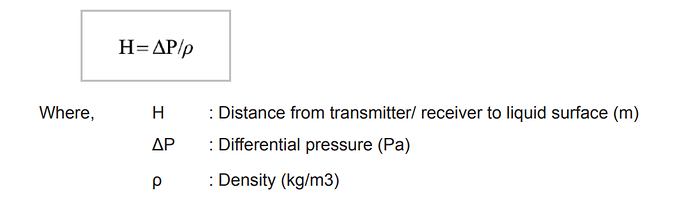

The differential pressure from the diaphragm is detected by a piezoelectric semiconductor element.

The output signal (4 mA – 20 mA DC) generated by the converter is changed to analog data in the central monitor and transmitted.

The following precautions should be taken related to the use of differential pressure type level gauge:

• The installed position of differential pressure transmitter should be lower than the minimum liquid level

• When the density of the liquid changes, correction is necessary (Span adjustment on the converter side is required)

• If the liquid has pulsing motion, the output of the differential pressure transmitter may become unstable