A diaphragm is a thin, flexible, flat or corrugated disk, held in place so that it is axially flexible. When pressure is applied to one side of the diaphragm it will deflect. Deflection is proportional to the pressure. The force opposing the pressure is the sum of the spring constant of the diaphragm, the pressure on the opposing side of the diaphragm, and the spring constant of any opposing spring. The sensitivity of a diaphragm increases as the diameter increases. The axial movement of the diaphragm can rotate a pointer or actuate a controller or transmitter by attaching the free end to a mechanical linkage.

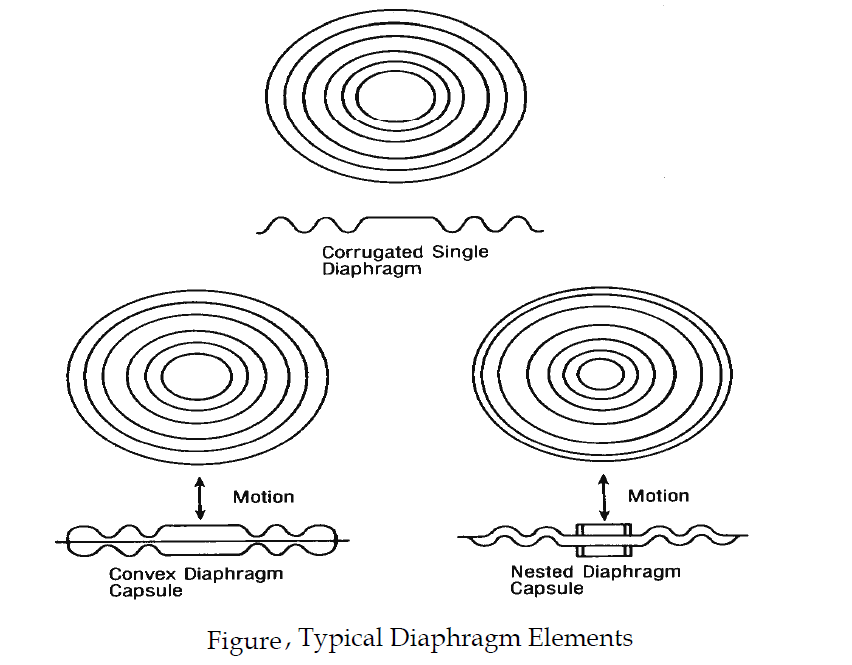

There are two types of diaphragm elements, elastic and limp. The elastic type uses the stiffness of the diaphragm to oppose the pressure applied. It is usually metallic and comes in two different configurations; single and capsular. The single diaphragm is, as its name implies, a single diaphragm either flat or with concentric corrugations.

The capsular diaphragm consists of two diaphragms welded together at their perimeters as shown in figure.

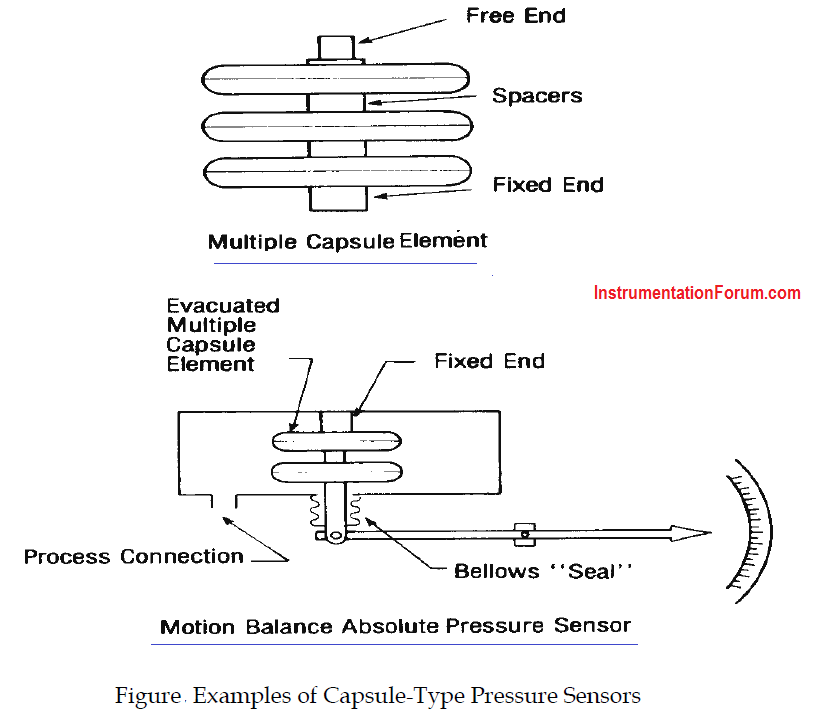

Capsules can be either convex or nested as illustrated. Capsules can be mounted in multiples to give more deflection for a given pressure as shown by below figure. Evacuated capsules are used for absolute pressure reference and single diaphragms for very sensitive measurements.