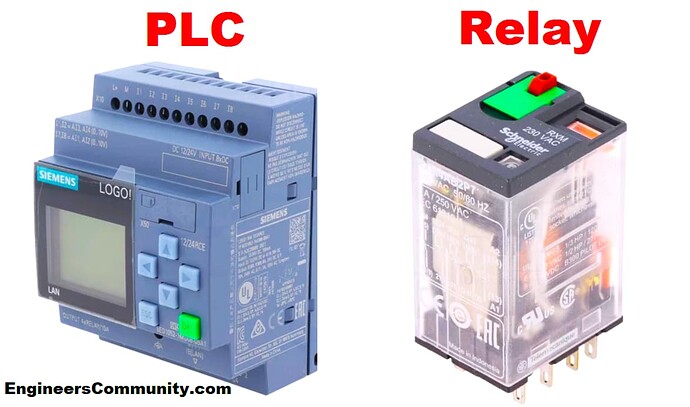

A Programmable Logic Controller (PLC) and a relay are both used in automation and control systems, but they serve different functions and have varying degrees of complexity.

PLC versus Relays

- Operation:

- Relays: A relay is an electromechanical switch that opens or closes contacts based on the application of electricity. It’s a fairly simple device, commonly used for switching applications.

- PLC: A PLC is a microprocessor-based device that can execute complex instructions. It can accept input from a variety of devices, execute a stored user program, and provide output to control devices. PLCs can handle multiple inputs and outputs, and process them in complex ways.

- Functionality:

- Relays: Relays can only perform simple switching operations. They are either on or off, based on whether or not current is applied to their control coil.

- PLC: PLCs, on the other hand, can perform a wide range of functions. They can perform simple on-off control, but they can also execute complex logic, timing, counting, arithmetic, and data manipulation operations. PLCs can also be networked together and communicate with other devices, such as computers and other PLCs.

- Flexibility and Scalability:

- Relays: If you need to modify the control logic of a relay-based system, you generally have to rewire the system, which can be time-consuming and costly. Also, scaling up a relay-based system can be challenging because it can quickly become complex and difficult to manage.

- PLC: PLCs, on the other hand, are highly flexible and scalable. You can easily modify the control program of a PLC without changing any wiring. This allows you to easily adapt to changing requirements. Also, PLCs can be easily expanded to handle more inputs and outputs, and they can handle complex systems more effectively.

- Cost and Maintenance:

- Relays: Relays are typically less expensive than PLCs, and they’re relatively easy to replace if they fail. However, maintaining a complex relay-based system can be labor-intensive and costly.

- PLC: PLCs are more expensive than relays, but they can reduce long-term costs by reducing wiring complexity and making maintenance and modifications easier. In addition, PLCs typically have diagnostic capabilities that can help in troubleshooting, which can further reduce maintenance costs.

Difference between PLC and Relays

| PLC (Programmable Logic Controller) | Relay | |

|---|---|---|

| Operation | Microprocessor-based device that executes complex instructions | Electromechanical switch that opens or closes contacts based on the application of electricity |

| Functionality | Can perform a wide range of functions: simple on-off control, complex logic, timing, counting, arithmetic, and data manipulation operations | Can only perform simple switching operations (either on or off) |

| Flexibility and Scalability | Highly flexible and scalable. The control program can be easily modified without changing wiring. Can be easily expanded to handle more inputs and outputs | If control logic needs modification, it generally requires rewiring, which can be time-consuming and costly. Scaling up can be challenging |

| Cost and Maintenance | More expensive initially but can reduce long-term costs by reducing wiring complexity and making maintenance/modifications easier. Has diagnostic capabilities for easier troubleshooting | Less expensive but maintaining a complex relay-based system can be labor-intensive and costly |

| Networking and Communication | Can be networked together and communicate with other devices such as computers and other PLCs | Typically standalone devices without network or communication capabilities |