Did you know that SCADA, HMI, PLC and DCS in today’s implementations are proving to be more costly than DCS for the exact same batch application or process?

Difference between SCADA, HMI, PLC and DCS systems ?

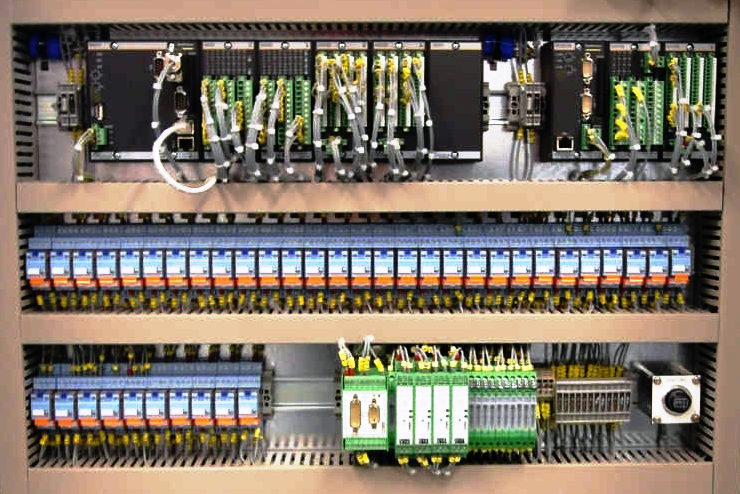

DCSs as a control solution for the continuous or batch process industries were traditionally know for being costly, bulky, and complex systems.

For larger systems this remains true, as engineers usually opt for cost effective PLCs and HMIs or SCADA for small scale applications. You may be surprised to know, however, that some things have changed.

Integrating independent PLCs, supervisory functionality, and the required operator interface can take up a large amount of time, and the focus is on making the technology work together, which doesn’t inherently reduce costs, or improve the profitability and quality of a plant.

A PLC/SCADA system may have part of or all of the following databases:

Each controller and its associated I/O

Batch/recipe and PLI

Fieldbus device management

Alarm management

Historian

Redundancy at all levels

Asset optimisation

For the complete system to function correctly, each of the above databases must be manually synchronized. In on-going system tuning and changes, this can be an unnecessary complication. Each time a change is made in a single database, all of the databases must be updated to reflect the changes made.

For example, a change made in an alarm setting in a control loop. There is no automatic connection between a PLC and the HMI/SCADA, which can become a problem when delicate tweaks must be made during the start up of a new application.

In today’s DCS, also called process control systems, allow a plant to integrate all of these databases into one, helping them to implement the entire system much more quickly.

This all-encompassing database is configured, designed, and operated from the same application! This can result in drastic cost reductions compared to PLC/SCADA (or HMI).

DCS’s reputation as large and expensive hardware no longer rings true today. In a small or medium size system, the price of hardware and software can be comparable to PLC/SCADA. The true benefit is the cost associated with the workflow, which is simplified and minimized by the single database that the DCS runs.

Another common misconception about DCS is that it is biased toward control loops, while PLCs are biased toward discrete sequential applications. Today, DCS is quite comparable in both cost and functionality to a PLC in fast logic sequential tasks!

Take a look at the following steps to see how to save time and money with DCS:

1: System design

Control engineers using PLC/SCADA need to map out system integration between HMI, controller communications, alarming, and multiple controllers for each new project.

The manual mapping process is prone to error and can take a large amount of time. It’s also neccesary for engineers to learn multiple software tools, which is also quite time consuming.

In the DCS approach, everything above is automatically configured. One software tool is used to set up the single database that each system component uses. Depending how much HMI and alarming is designed into the system, savings of 15-25% can be achieved.

2: Programming

System communications, HMI, alarming, and PLC/SCADA control logic are programmed independently, making engineers responsible for the integration of multiple databases. Scalability, alarm levels, and tag locations all need to be manually duplicated in every part of the system, and only basic control is available.

Functionality extensions are created on a per application basis, which is a complex and tedious method neccessary to operate and maintain the resulting non-standard applications.

With DCS, alarms, HMI faceplates, and system communications are automatically configured, and these elements are set up only once. Redundancy is set up quickly and simply. Can lead to savings of 15-45%!

3: Commissioning and start up

Normally, testing of a PLC/HMI system happens at the job site after the wiring is finished. Owing to the high cost and time consuming nature of offline simulation, offline tests are rarely done.

Using DCS, process control systems have the ability to simulate the process based on the HMI, alarms, and logic that are to be used by the plant operator, before the wiring is finished. This results in significant time savings of 10-20% depending on how complex the commissioning and start up is.

4: Troubleshooting

Powerful troubleshooting options are offered by PLC/SCADA only if they are programmed into the system by the engineer.

With DCS, the operator has automatic access to all of the information based on the logic being executed in the controllers. This saves time in diagnosing problems and getting your plant back up and running! Savings vary from 10-40%.

5: Meeting process requirements

Changing the control logic to meet requirements is relatively easy in PLC/SCADA. However, this process becomes more complex with additional requirements to integrate new functionality to the operator stations.

In addition, changes should be but are seldom documented. If one changed an input point to a new tag or address, the change must be manual entered across the entire system.

With the DCS method, changing or adding logic is greatly simplified. When changes are made, the data is automatically propagated thought the entire system.

The system is changed with a single change in logic, and this results in far less errors, as well as savings of 20-25%.

6: Operator training

The developer of a PLC/SCADA application is responsible for the training of the operator. There is no manufacturer training, as each screen, faceplate or alarm management function can be set up in different ways.

With DCS, training is available from the process control vendor! This is made possible by the standardization of the information presented to the operator.

This can greatly reduce training costs and improve quality, as there is a common, expected operator interface on every application, no matter who is implementing the system. 10-15% reduction in training costs is common.

7: Documentation

Based on each part of the complete system, PLC/SCADA requires that documentation be updated to reflect element changes. Sadly, these documentation rarely happen, causing later issues with troubleshooting and consistency.

As the control logic is changed with DCS, documentation is automatically creates for all parts of the system. Depending on the type of system being put in place, this can result in savings of 30-50%.

8: Final thoughts

When planning to use PLC/SCADA for your process or batch applications, keep in mind that you application may be a candidate for DCS solutions!

A DCS solution can result in better control, reduced cost, added functionality, and reduced return on investment. For the economical and forward-thinking, DCS may very well be the best option.