Following Types of F&G Devices are most prevalent in the Industry

H2S Gas Detector

These are generally solid state, continuous absorption diffusion type sensor. Transmitter heading shall be self contained, micro-processor controlled.It is generally provided with flame arrest.

Detection should be fast and reliable.More importance is give response rather than precision. Typical response time is less than 40s and detection level is 20ppm of H2S

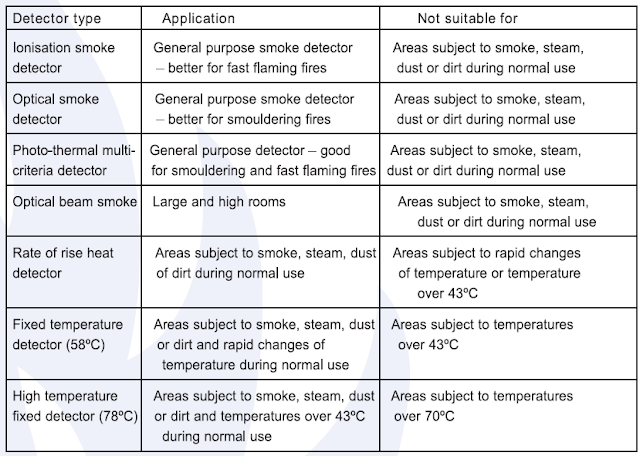

Smoke Detector

A very good pdf for the gas detection is available at Link.

As a general rule, when locating gas detectors, the following points shall be assessed to ensure that detection is effective:

• Product composition phase (liquid/vapour);

• Operating pressure;

• Density of gas;

• Location of release sources;

• Congestion;

• Potential for accumulation;

• Detection distance away from the release source (detectors close to release sources may not be as effective as detectors places at a distance away);

• Poisoning materials which can affect the detector technology;

• Area coverage.

Line Of Sight Flammable (HC, Ethylene Oxyde) and Toxic Gas Detectors (H2S)

The maximum distance between transmitter and receiver must not exceed 60 LOS shall be installed according to the following guidelines:

• For natural gas: beam-path shall be parallel to the ground floor and above the height of most of the valves and flanges in the vicinity;

• For toxic gases (except for H2S): beam-path shall be parallel to the ground floor at ‘breathing height’ (~1.4m – 1.7m);

• For H2S toxic gases (which is heavier than air): beam-path shall be parallel to the ground floor at a height between 1m and 1.2m;

• For gas mixtures significantly denser than air: beam-path shall be mounted parallel to the ground floor and below all potential leak sources;

• For gas mixtures significantly lighter than air: beam-path shall be parallel to the ground floor and above all potential leak sources.

LOS detectors require a clear and open (i.e. unobstructed) path approximately 0.3m in diameter and therefore shall be applied with caution in congested areas. To prevent temporary obstruction, it is advised that floor markings be applied to show the location of open paths. Alarm filtering and time delay shall also be available to avoid spurious alarms with human obstructions.

Furthermore, to avoid damage by ingress of splash water, LOS shall not be installed lower than 1 m above grade or ground level.

Flammable and H2S Point Gas Detector

Flammable and toxic point gas detectors shall be located in accordance to the F&G mapping study in order to optimize gas detector location (including height), with the goal to detect a gas cloud sufficiently early such that hazardous accumulations are prevented.

When H2S fluid is handled in flammable process streams, the following shall apply

- For a concentration of H2S in the production stream exceeding 500 ppm, H2S gas detectors shall be used;

- If H2S is present in a stream mixed with CO and at sufficient proportion (> 1000 ppm), then only H2S gas detector will be installed due to their earlier detection time.

For process streams with a concentration of H2S not exceeding 500 ppm, flammable gas detectors may be used.