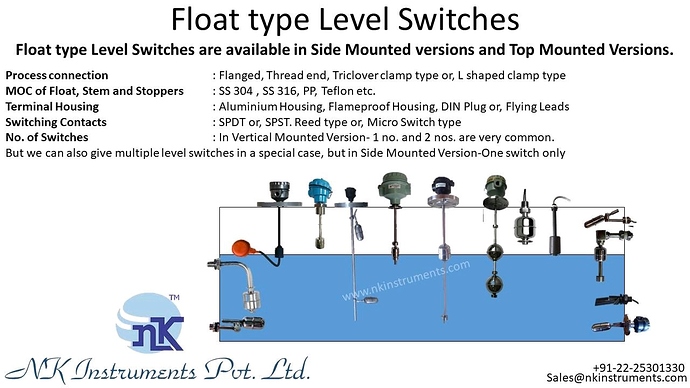

Different Types of Float Level Switch diagram.

Level sensors detect the level of liquids and other fluids and fluidized solids, including slurries, granular materials, and powders that exhibit an upper free surface.

Substances that flow become essentially horizontal in their containers (or other physical boundaries) because of gravity whereas most bulk solids pile at an angle of repose to a peak. The substance to be measured can be inside a container or can be in its natural form (e.g., a river or a lake).

The level measurement can be either continuous or point values. Continuous level sensors measure level within a specified range and determine the exact amount of substance in a certain place, while point-level sensors only indicate whether the substance is above or below the sensing point. Generally the latter detect levels that are excessively high or low.

Applications

Level switches have a wide variety of level detection and control applications, such as:

• the level monitoring and control of refrigerant or oil levels in HVAC systems

• the control of potentially dangerous chemicals found in processing applications

• the monitoring of wastewater levels

• the monitoring of powder and liquid food item levels during food production and packaging

• the level measurement of drug ingredient bulk quantities.

Some of the many industries in which they are common include HVAC, food and beverage, pharmaceutical, water treatment, manufacturing, oil and gas, and hydraulics.

Types

While they make many different types of level switches, there are a few specific types that level switch manufacturers make most often to fulfill industrial application requirements. These include liquid level switches, solid level switches, float level switches, spinning rotary level switches, mechanical level switches, non-mechanical level switches, displacer level switches, chambered level switches, capacitance level sensors, ultrasonic level switches, optical level switches, and laser level switches.

Liquid level switches exclusively measure and control liquids. They provide info on liquid details like flow, volume, and pressurization. Most often, they are found in transmission systems and storage systems.

Solid level switches are those switches that measure and control solid masses.

Float level switches use buoyancy. Designed to measure liquid levels, float level switches consist of a buoy or float, which sits on the liquid, and an electrical circuit. As material rises and falls, the float moves along with it, and if and when the float reaches a certain point, it triggers an electrical circuit, which closes the switch and sends a signal to the switch’s control equipment.

Spinning rotary level switches are a good example of a solid level switch. They measure levels of granular solids at different levels inside storage containers. Spinning rotary level switches employ blades or paddles that rotate around an axis that stop only when they are interrupted by the presence of a solid. When this interruption happens, the control equipment receives the signal that the switch elevation has been reached.

Mechanical level switches measure contents mechanically, via direct physical contact. Examples of common mechanical level float switches include displacer level switches, rotary tank level indicators, and float level switches.

Nonmechanical level switches measure materials without physical contact. They include level switch types such as optical level switches, laser level switches, capacitance level sensors, and ultrasonic level sensors.

Displacer level switches , a type of liquid level sensor, are closely related to float level switches. Like them, displacer level switches also measure and monitor liquid level changes with the force of buoyancy.

Chambered level switches are named after the casing, or chamber, in which their switch mechanism is encased. They are mostly used as liquid and solid level switches, but they can sometimes be used to control the flow of materials in and out of the container they are monitoring.

Capacitance level sensors use electrical signals to detect the presence of organic and aqueous liquids, solids, and slurries alike.

Ultrasonic level switches measure level changes via the transmission and reflection of ultrasonic waves.

Optical level switches or sensors are used to sense changes in levels of sediments, suspended solids, and liquids. They do so by projecting an infrared light from an infrared diode (LED) and noting changes in its transmission.

Laser level switches , or laser diode level switches, use laser diode technology to measure and control solids like pellets, granular materials, and bulk items. Laser diodes are semiconductor devices. They are quite similar to light-emitting diodes. Most often, they work using light beams from fiber lasers (fiber laser level switches). Laser systems are extremely accurate and reliable, and users can adjust the size of the light beams. Per their nature, you must practice proper safety measures when using laser diode level switches.