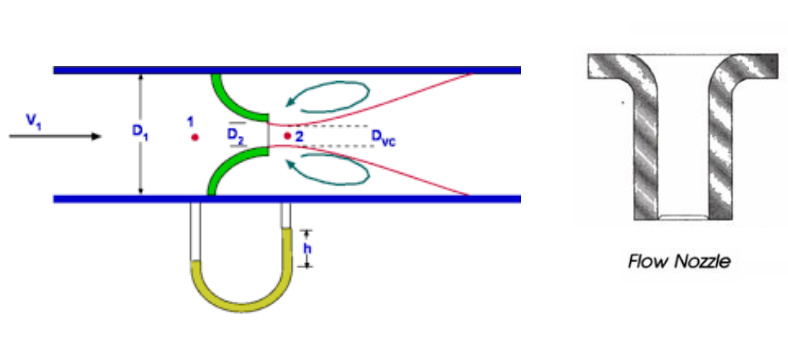

Flow Nozzle

The flow nozzles are used for flow measurements at high fluid velocities and are more rugged and more resistant to erosion than the sharp edged orifice plate.

Basically, there are two types of flow nozzles, the long-radius flow nozzles and the I.S.A. (International Federation of the National Standardizing Associations) flow nozzle.

A flow nozzle consists of a convergent inlet whose shape is a quarter ellipse, and a cylindrical throat

Differential pressure measurement taps are normally located one pipe diameter upstream and one-half diameter downstream from the inlet faces of the nozzle.

For a given diameter and a given differential pressure, it allows measurement of flow rates almost 65% more than that of the orifice plate.

Flow nozzles are manufactured commonly from materials such as stainless steel or chrome-moly steel.

They are made commercially in various configurations, viz. flange type, holding ring type, weld-in type, and throat type.

Flow nozzles should be used at Reynolds numbers of 50,000 or above.

However, data is available for Reynolds number down to 6,000; so it is possible to use nozzles with more viscous fluids.

Flow nozzles have very high coefficients of discharge, typically 0.99 or greater, and a wide range of beta ratios of 0.2 to 0.8.

Advantages:

- Its permanent pressure loss is lower than that for an orifice plate.

- It is available in numerous materials.

- It is useful for fluids containing solids that settle.

- It is widely accepted for high-pressure and temperature steam flow.

Disadvantages:

- Its cost is higher than orifice plate.

- It is limited to moderate pipe sizes.

- It requires more maintenance (t is necessary to remove a section of pipe to inspect or install it.)