Turbine flow meter

Principle:

Theturbine flowmeter is used for the measurement of liquid, gas and very low flow rates. It works on the basic principle of turbine.

Construction:

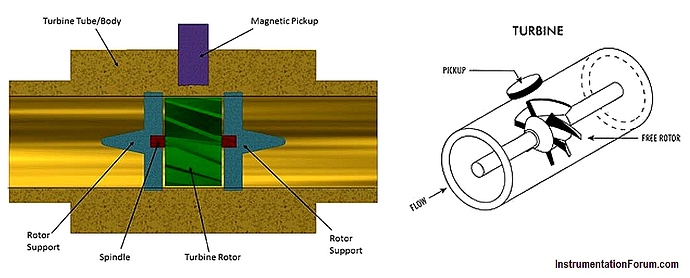

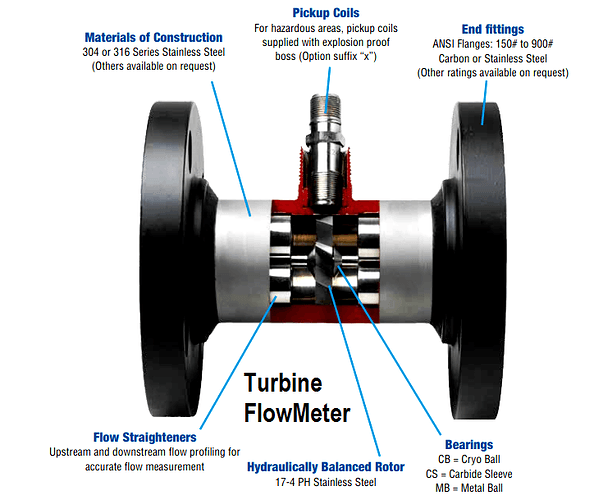

- It consists of a multi-bladed rotor (turbine wheel) which is mounted at right angles to the axis of the flowing liquid, as shown in Fig.

- The rotor is supported by ball or sleeve bearings on a shaft which is retained in the flowmeter housing by a shaft-support section. The rotor is free to rotate about its axis.

Working:

- The flowing fluid impinges on the turbine blades (rotor), imparting a force to the blade surface which causes the rotation of the rotor.

- The speed of rotor is directly proportional to the fluid velocity, and hence to volumetric flow rate when it is at a steady rotational speed.

- The speed of rotation is monitored in most of the meters by a magnetic pickup coil, which is fitted to the outside of the meter housing.

- The magnetic-pickup coil consists of a permanent magnet with coil windings which is mounted in close proximity to the rotor but internal to the fluid channel.

- As each rotor blade passes the magnetic-pickup coil, it generate a voltage pulse which is a measure of the flow rate, and the total number of pulses give a measure of the total flow.

- The electrical voltage pulses can be totalled; subtracted and manipulated by digital techniques so that a zero error characteristic of digital handling is provided from the pulse generator to the final read out.

The K factor (i e, the number of pulses generated per gallon of flow) is given as

K = (Tk x f) / Q

where,

K = pulses per volume unit, Tk =a time constant in min,

Q =a volumetric flow rate in gpm and f= frequency in Hz

Advantages:

- No external power supply for Rotating vane and Woltman meters

- Turbine flowmeters suitable for cryogenic liquids

- Turbine flowmeters usable at extreme temperatures and pressures

Disadvantages:

- Limited choice of materials

- Only for low viscosities

- Moving parts, wear

- Sensitive to contamination

- Axial flow totalizers are flow profile sensitive

- Inlet and outlet sections required (not for rotating vane meters)

- Affected by overloading and quick changes at high differential pressure, danger of over speeding

- Vibration sensitive

Check out