Free Download Safety Instrumented System (SIS) engineering Book.

The Safety Instrumented System is an instrumentation and control system that detects out-of-control process conditions, and automatically returns the process to a safe state. It is the last line - or near last line - of defense against a chemical process hazard, and it is not part of the Basic Process Control System. The last line of defense is what differentiates a Safety Instrumented System from the Basic Process Control System, which is used for normal regulatory process control.

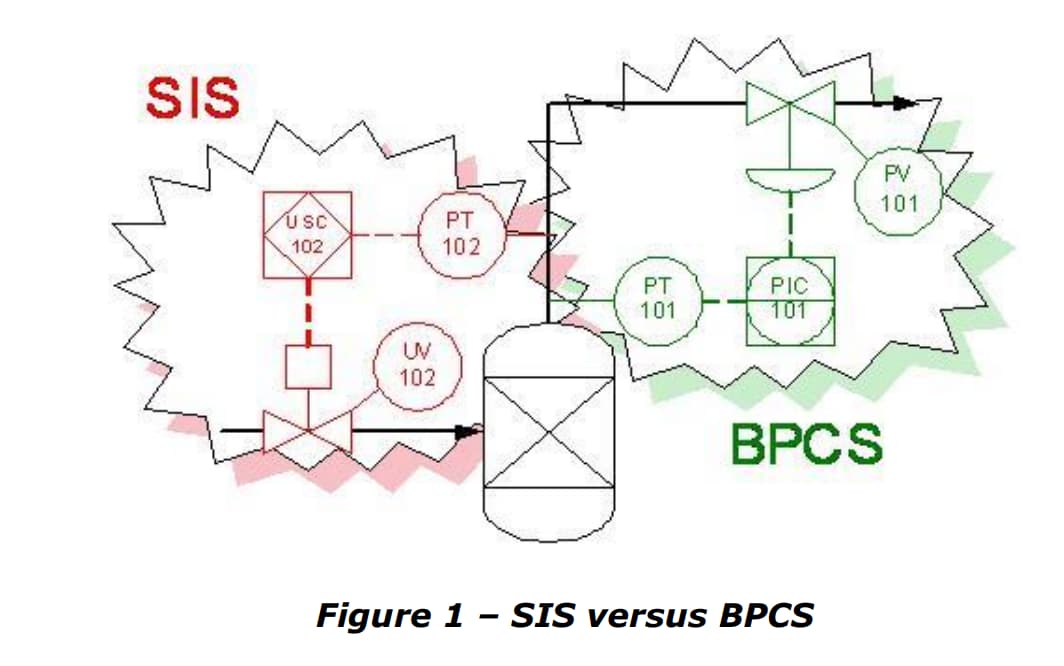

Figure 1 demonstrates how Safety Instrumented Systems are different from Basic Process Control Systems, or the BPCS. In this example, pressure is a potential hazard.

Pressure is normally controlled by a regulatory control loop, shown as the Basic Process Control System, which modulates a pressure control valve.

An independent high-pressure shutdown function is implemented in a Safety Instrumented System. It is independent in as much as the components used in the BPCS and the SIS are separate, physically and functionally.

This includes the sensor components, the logic solver, as well as the final control elements. SIS are generally independent, both physically and functionally, from the BPCS in order to ensure that any condition, which might result in an out-of-control process parameter in the BPCS, is safeguarded by the SIS, regardless of the function of the BPCS.

The SIS will include three types of components including sensor components, a logic solver component, and final control elements. Together these components make up the Safety Instrumented System, which detects out-of-control process conditions, and automatically returns the process to a safe condition, regardless of the functioning of the Basic Process Control System. In this case, the SIS could include a programmable system, or a non-programmable system.

Download Book

Safety Instrumented System (SIS) Book.pdf (2.3 MB)