A distributed control system (DCS) refers to a control system usually of a manufacturing system, process or any kind of dynamic system, in which the controller elements are not central in location (like the brain) but are distributed throughout the system with each component sub-system controlled by one or more controllers.

DCS

The entire system of controllers is connected by networks for communication and monitoring. DCS is a very broad term used in a variety of industries, to monitor and control distributed equipment.

- Electrical power grids and electrical generation plants

- Environmental control systems

- Traffic signals

- Radio signals

- Water management systems

- Oil refining plants

- Chemical plants

- Pharmaceutical manufacturing

- Sensor networks

- Dry cargo and bulk oil carrier ships

Elements

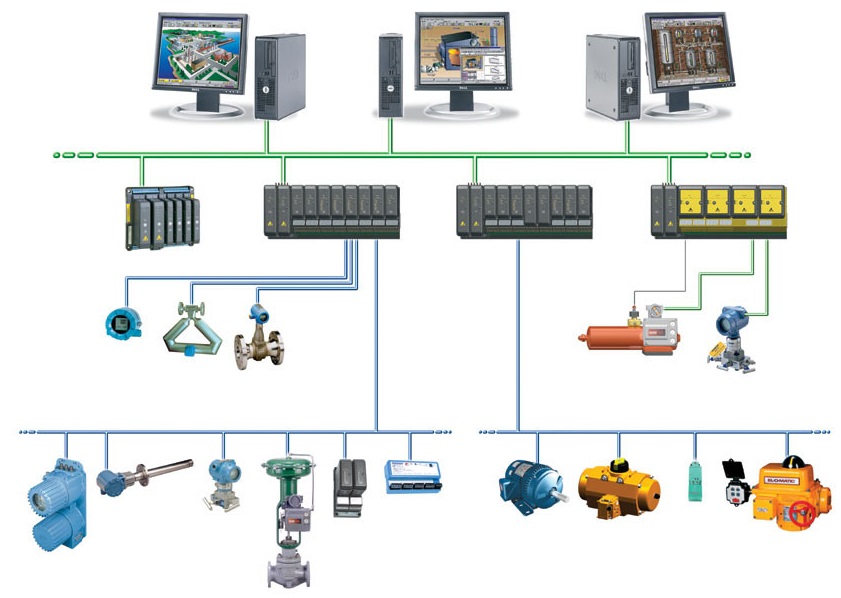

A DCS typically uses custom designed processors as controllers and uses both proprietary interconnections and communications protocol for communication. Input and output modules form component parts of the DCS. The processor receives information from input modules and sends information to output modules.

The input modules receive information from input instruments in the process (a.k.a. field) and transmit instructions to the output instruments in the field. Computer buses or electrical buses connect the processor and modules through multiplexer or demultiplexers. Buses also connect the distributed controllers with the central controller and finally to the Human-Machine Interface (HMI) or control consoles. See Process Automation System.

Elements of a distributed control system may directly connect to physical equipment such as switches, pumps and valves or may work through an intermediate system such as a SCADA system.

Applications

Distributed Control Systems (DCSs) are dedicated systems used to control manufacturing processes that are continuous or batch-oriented, such as oil refining, petrochemicals, central station power generation, pharmaceuticals, food & beverage manufacturing, cement production, steelmaking, and papermaking. DCSs are connected to sensors and actuators and use setpoint control to control the flow of material through the plant.

The most common example is a setpoint control loop consisting of a pressure sensor, controller, and control valve. Pressure or flow measurements are transmitted to the controller, usually through the aid of a signal conditioning Input/Output (I/O) device. When the measured variable reaches a certain point, the controller instructs a valve or actuation device to open or close until the fluidic flow process reaches the desired setpoint.

Large oil refineries have many thousands of I/O points and employ very large DCSs. Processes are not limited to fluidic flow through pipes, however, and can also include things like paper machines and their associated variable speed drives and motor control centers, cement kilns, mining operations, ore processing facilities, and many others.

A typical DCS consists of functionally and/or geographically distributed digital controllers capable of executing from 1 to 256 or more regulatory control loops in one control box. The input/output devices (I/O) can be integral with the controller or located remotely via a field network.

Today’s controllers have extensive computational capabilities and, in addition to proportional, integral, and derivative (PID) control, can generally perform logic and sequential control.

DCSs may employ one or several workstations and can be configured at the workstation or by an off-line personal computer.

Local communication is handled by a control network with transmission over twisted pair, coaxial, or fiber optic cable. A server and/or applications processor may be included in the system for extra computational, data collection, and reporting capability.

History

Early minicomputers were used in the control of industrial processes since the beginning of the 1960s. The IBM 1800, for example, was an early computer that had input/output hardware to gather process signals in a plant for conversion from field contact levels (for digital points) and analog signals to the digital domain.

The first industrial control computer system was built 1959 at the Texaco Port Arthur, Texas, refinery with an RW-300 of the Ramo-Wooldridge Company [1].

The DCS was introduced in 1975. Both Honeywell and Japanese electrical engineering firm Yokogawa introduced their own independently produced DCSs at roughly the same time, with the TDC 2000 and CENTUM systems, respectively. US-based Bristol also introduced their UCS 3000 universal controller in 1975. In 1980, Bailey (now part of ABB) introduced the NETWORK 90 system.

Also in 1980, Fischer & Porter Company (now also part of ABB) introduced DCI-4000 (DCI stands for Distributed Control Instrumentation).

The DCS largely came about due to the increased availability of microcomputers and the proliferation of microprocessors in the world of process control. Computers had already been applied to process automation for some time in the form of both Direct Digital Control (DDC) and Set Point Control.

In the early 1970s Taylor Instrument Company, (now part of ABB) developed the 1010 system, Foxboro the FOX1 system and Bailey Controls the 1055 systems. All of these were DDC applications implemented within mini-computers (DEC PDP 11, Varian Data Machines, MODCOMP etc) and connected to proprietary Input/Output hardware. Sophisticated (for the time) continuous as well as batch control was implemented in this way.

A more conservative approach was Set Point Control , where process computers supervised clusters of analog process controllers. A CRT-based workstation provided visibility into the process using text and crude character graphics. Availability of a fully functional graphical user interface was a way away.

Central to the DCS model was the inclusion of control function blocks. Function blocks evolved from early, more primitive DDC concepts of “Table Driven” software.

One of the first embodiments of object-oriented software, function blocks were self contained “blocks” of code that emulated analog hardware control components and performed tasks that were essential to process control, such as execution of PID algorithms.

Function blocks continue to endure as the predominant method of control for DCS suppliers, and are supported by key technologies such as Foundation Fieldbus today.

Digital communication between distributed controllers, workstations and other computing elements (peer to peer access) was one of the primary advantages of the DCS. Attention was duly focused on the networks, which provided the allimportant lines of communication that, for process applications, had to incorporate specific functions such as determinism and redundancy.

As a result, many suppliers embraced the IEEE 802.4 networking standard. This decision set the stage for the wave of migrations necessary when information technology moved into process automation and IEEE 802.3 rather than IEEE 802.4 prevailed as the control LAN.

The Network Centric Era of the 1980s

The DCS brought distributed intelligence to the plant and established the presence of computers and microprocessors in process control, but it still did not provide the reach and openness necessary to unify plant resource requirements. In many cases, the DCS was merely a digital replacement of the same functionality provided by analog controllers and a panelboard display.

This was embodied in The Purdue Reference Model (PRM) that was developed to define Manufacturing Operations Management relationships. PRM later formed the basis for ISA95 standards activities today.

In the 1980s, users began to look at DCSs as more than just basic process control. A very early example of a Direct Digital Control DCS was completed by the Australian business Midac in 1981-1982 using R-Tec Australian designed hardware.

The system installed at the University of Melbourne used a serial communications network, connecting campus buildings back to a control room “front end”. Each remote unit ran 2 Z80 microprocessors whilst the front end ran 11 in a Parallel Processing configuration with paged common memory to share tasks and could run up to 20,000 concurrent controls objects.

It was believed that if openness could be achieved and greater amounts of data could be shared throughout the enterprise that even greater things could be achieved. The first attempts to increase the openness of DCSs resulted in the adoption of the predominant operating system of the day: UNIX. UNIX and its companion networking technology TCP-IP were developed by the Department of Defense for openness, which was precisely the issue the process industries were looking to resolve.

As a result suppliers also began to adopt Ethernet-based networks with their own proprietary protocol layers. The full TCP/IP standard was not implemented, but the use of Ethernet made it possible to implement the first instances of object management and global data access technology. The 1980s also witnessed the first PLCs integrated into the DCS infrastructure. Plant-wide historians also emerged to capitalize on the extended reach of automation systems.

The first DCS supplier to adopt UNIX and Ethernet networking technologies was

Foxboro, who introduced the I/A Series system in 1987.

The Application Centric Era of the 1990s

The drive toward openness in the 1980s gained momentum through the 1990s with the increased adoption of Commercial off-the-shelf (COTS) components and IT standards. Probably the biggest transition undertaken during this time was the move from the UNIX operating system to the Windows environment. While the realm of the real time operating system (RTOS) for control applications remains dominated by real time commercial variants of UNIX or proprietary operating systems, everything above real-time control has made the transition to Windows.

The introduction of Microsoft at the desktop and server layers resulted in the development of technologies such as OLE for Process Control (OPC), which is now a de facto industry connectivity standard. Internet technology also began to make its mark in automation and the DCS world, with most DCS HMI supporting Internet connectivity.

The ’90s were also known for the “Fieldbus Wars”, where rival organizations competed to define what would become the IEC fieldbus standard for digital communication with field instrumentation instead of 4-20 milliamp analog communications. The first fieldbus installations occurred in the 1990s.

Towards the end of the decade, the technology began to develop significant momentum, with the market consolidated around Foundation Fieldbus and Profibus PA for process automation applications. Some suppliers built new systems from the ground up to maximize functionality with fieldbus, such as Honeywell with Experion & Plantscape SCADA systems, ABB with System 800xA, Emerson Process Management with the DeltaV control system, Siemens with the Simatic PCS7 and azbil from Yamatake with the Harmonas-DEO system.

The impact of COTS, however, was most pronounced at the hardware layer. For years, the primary business of DCS suppliers had been the supply of large amounts of hardware, particularly I/O and controllers.

The initial proliferation of DCSs required the installation of prodigious amounts of this hardware, most of it manufactured from the bottom up by DCS suppliers. Standard computer components from manufacturers such as Intel and Motorola, however, made it cost prohibitive for DCS suppliers to continue making their own components, workstations, and networking hardware.

As the suppliers made the transition to COTS components, they also discovered that the hardware market was shrinking fast. COTS not only resulted in lower manufacturing costs for the supplier, but also steadily decreasing prices for the end users, who were also becoming increasingly vocal over what they perceived to be unduly high hardware costs.

Some suppliers that were previously stronger in the PLC business, such as Rockwell Automation, Siemens, were able to leverage their expertise in manufacturing control hardware to enter the DCS marketplace with cost effective offerings, while the stability/scalability/reliability and functionality of these emerging systems are still improving.

The traditional DCS suppliers introduced new generation DCS System based on the latest Communication and IEC Standards, which resulting in a trend of combining the traditional concepts/functionalities for PLC and DCS into a one for all solution—named “Process Automation System”.

The gaps among the various systems remain at the areas such as: the database integrity, pre-engineering functionality, system maturity, communication transparency and reliability. While it is expected the cost ratio is relatively the same (the more powerful the systems are, the more expensive they will be), the reality of the automation business is often operating strategically case by case. The current next evolution step is called Collaborative Process Automation Systems.

To compound the issue, suppliers were also realizing that the hardware market was becoming saturated. The lifecycle of hardware components such as I/O and wiring is also typically in the range of 15 to over 20 years, making for a challenging replacement market.

Many of the older systems that were installed in the 1970s and 1980s are still in use today, and there is a considerable installed base of systems in the market that are approaching the end of their useful life. Developed industrial economies in North America, Europe, and Japan already had many thousands of DCSs installed, and with few if any new plants being built, the market for new hardware was shifting rapidly to smaller, albeit faster growing regions such as China, Latin America, and Eastern Europe.