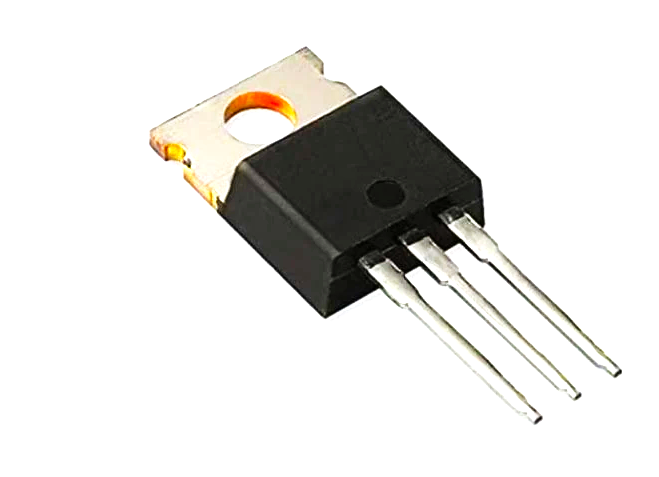

Silicon Controlled Rectifiers (SCR), also known as thyristors, are widely used in the world of electronics for various applications, including power control and rectification.

SCR Testing

To ensure their functionality and integrity, it’s important to conduct a few key tests.

1. Visual Inspection

Before testing an SCR with electrical methods, a visual inspection can help detect physical damage such as cracks, burn marks, or corrosion.

2. Multimeter Diode-Check Function Test

To test an SCR, a digital multimeter (DMM) is often used. The following steps will guide you through the testing process:

Step 1: Turn off power to the circuit and discharge all power supplies. Disconnect the SCR from the circuit.

Step 2: Set the multimeter to the diode-check mode.

Step 3: Connect the positive (red) lead of the multimeter to the anode and the negative (black) lead to the cathode of the SCR. The multimeter should show an open circuit (or infinite resistance).

Step 4: Now reverse the leads. Connect the negative lead to the anode and the positive lead to the cathode. The multimeter should again show an open circuit.

Step 5: To test the gate, connect the positive lead to the gate and the negative lead to the cathode. The multimeter should show an open circuit.

Step 6: Now reverse the leads. Connect the negative lead to the gate and the positive lead to the cathode. The multimeter should again show an open circuit.

If the SCR shows a short circuit (zero resistance) or conducts in one of these tests, it is defective and should be replaced.

3. Functionality Test

For a more definitive test, apply a voltage across the anode and cathode and use a low voltage to trigger the gate:

Step 1: Connect a DC voltage source (make sure it’s within the SCR’s specified voltage rating) across the anode and cathode, with the anode positive and the cathode negative. The SCR should not conduct, and no current should flow.

Step 2: Apply a small positive voltage to the gate (with respect to the cathode). This should trigger the SCR, causing it to conduct, and current should flow between the anode and cathode.

Always consider safety first. Only conduct these tests if you have the necessary technical skills and experience. If you’re unsure or uncomfortable testing the component yourself, consider seeking help from a trained professional.