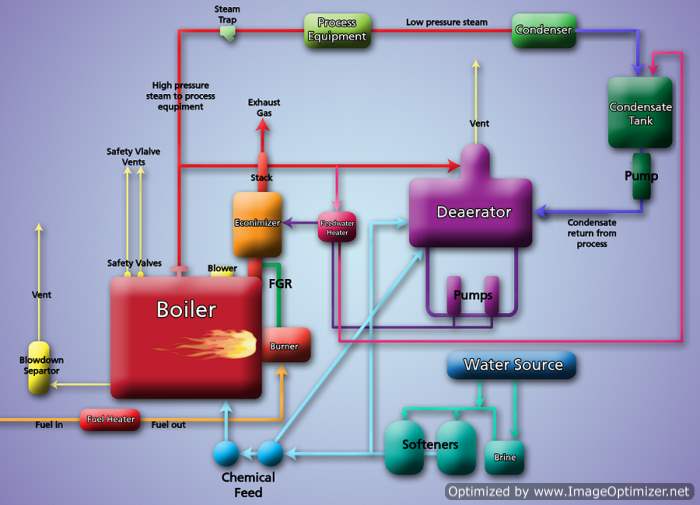

Boiler systems are comprised of the major components described below

Feedwater Heaters

Feedwater heaters are energy recovery devices generally found only in large steam generating plants where all of the steam generated is not reduced to condensate by the steam user.

This “waste steam” is reduced to condensate for return to the boiler in the feed-water heater. The boiler feed-water is used as a cooling medium to reduce the steam to condensate, which increases the temperature of the feed-water and, thereby, increases the thermal efficiency of the boiler.

Fuel Heater

Many boilers firing heavy fuel oil require fuel heaters to reduce the fuel viscosity, so the fuel can be atomized by the burner system for complete combustion.

Deaerators

A deaerator is a special case of feedwater heater that is designed to promote the removal of non-condensable gases from the boiler feedwater. The principal gases of concern are oxygen, carbon dioxide, and ammonia, which are major contributors to boilers, and steam and condensate piping corrosion problems.

In small steam plants, a portion of the steam generated by the boiler is used to operate the deaerator if “waste steam” is not available. Failure to maintain and properly operate the deaerator can lead to early failure of the boiler, steam using equipment, and the steam and condensate piping.

Pumps

In most hot water systems, the system circulating pumps are electric motor-driven, end suction centrifugal pumps. In steam systems, the condensate return pumps are typically electric motor-driven, end suction, centrifugal or turbine-type pumps.

Feed-water pumps are generally electric motor-driven, multiple-stage, end suction centrifugal pumps. The shutoff head of the pump must be greater than the steam or hot water system operating pressure.

Combustion Air Blowers

In many packaged boiler installations, the combustion air fan is designed and provided by the boiler manufacturer and is integral with the boiler housing.

In installations where a stand-alone fan is provided, low-pressure centrifugal blowers are commonly used. An important characteristic of the blower is the ability to maintain a relatively constant air pressure over a wide range of airflow.

Flue

Flues (boiler firebox exhaust duct or boiler discharge stack) must be large enough to conduct the products of combustion away from the boiler with a minimum of duct friction loss.

Flues may be fabricated from any material suitable for the operating temperature and pressure. Common materials of construction associated with packaged boiler installations are carbon steel and stainless steel.

Economizer

An economizer is an energy recovery device that uses the hot exhaust gases from the boiler (waste heat) to heat combustion air or feedwater.

Steam Traps

Steam traps are installed throughout steam systems to remove condensate (spent steam), air, and non-condensable gases from the steam system. There are five types of steam traps in general use today, as described below.

-

The heart of a ‘’‘balanced pressure thermostatic trap’’’ is the flexible bellows that moves the valve head from its seat to discharge the condensate. The bellows is filled with a volatile fluid and hermetically sealed. The fluid has a pressure-temperature relationship that closely parallels, but is approximately 10 degrees Fahrenheit below that of steam.

-

The ‘’‘liquid expansion steam trap’’’ has for its operating element a liquid-filled cartridge. Within this cartridge is a hermetically sealed bellows which is attached to the valve head and plunger.

-

‘’‘Float and thermostatic steam traps’’’ provide immediate and continuous discharge of condensate, air, and non-condensables from a steam system as soon as they reach the trap. The trap consists of a ball float connected by a lever assembly to the main valve head. As condensate reaches the trap, the ball float rises, positioning the valve to discharge the condensate at the same rate as it reaches the trap.

-

The ‘’‘inverted bucket steam trap’’’ is a type of trap with an inverted bucket attached to the valve head by a lever mechanism and operates to open and close the trap. When condensate enters the trap, a water seal is formed around the bottom of the inverted bucket which, since it is filled with air, becomes buoyant and rises and closes the trap. A small hole in the top of the inverted bucket allows air to escape with condensate taking its place inside the bucket. The inverted bucket loses its buoyancy and sinks to the trap bottom, opening the valve to discharge the condensate.

-

‘’‘Thermodynamic steam traps’’’ are a type of steam trap that responds to differences in kinetic energy between steam and condensate to open and close the valve for discharging condensate.

Piping

Piping two-inches and smaller used in steam and hot water systems is typically Schedule 80, American Society for Testing and Materials (ASTM) A 106, Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service (1999), Grade B, steel pipe with threaded joints and carbon steel fittings. Piping larger than two-inches is typically standard weight, ASTM A 106, Grade B, steel pipe with flanged joints and carbon steel fittings.