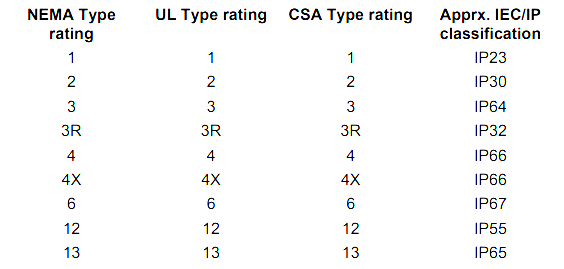

NEMA enclosure standards represent an enclosure’s ability to protect against the external environment.

NEMA Enclosure Standard

The following represent brief summaries of the NEMA standard.

Type 1

Intended for indoor use primarily to provide a degree of protection against (hand) contact with the enclosed equipment. Sometimes known as a “finger-tight” enclosure.

This is the least costly enclosure, but is suitable only for clean, dry environments.

Type 2

Intended for indoor use primarily to provide a degree of protection against limited amounts of falling dirt and water.

Type 3

Intended for outdoor use primarily to provide a degree of protection against windblown dust, rain, and sleet; undamaged by ice which forms on the enclosure.

Type 3R

Intended for outdoor use primarily to provide a degree of protection against falling rain and sleet; undamaged by ice which forms on the enclosure. This is the most common outdoors enclosure.

Type 4

Intended for indoor or outdoor use primarily to provide a degree of protection against windblown dust and rain, splashing water, and hose directed water; undamaged by ice which forms on the enclosure.

Type 4X

Intended for indoor or outdoor use primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing water, and hose directed water; undamaged by ice which forms on the enclosure.

This is the most common enclosure in “food” environments. Commonly made from stainless steel (expensive) or fiberglass (cheap).

Type 6

Intended for use indoors or outdoors which occasional temporary submersion is encountered.

Type 6P

Intended for use indoors or outdoors which occasional prolonged submersion is encountered. Corrosion protection. This type is recommended when extensive washdowns are performed.

Type 12

Intended for use indoors to provide a degree of protection against dust, falling dirt, and dripping noncorrosive liquids. This is the most common type enclosure used in normal factory environments.

Type 13

Intended for use indoors to provide a drgree of protection against dust, and the spraying of water, oil, and noncorrosive coolant.