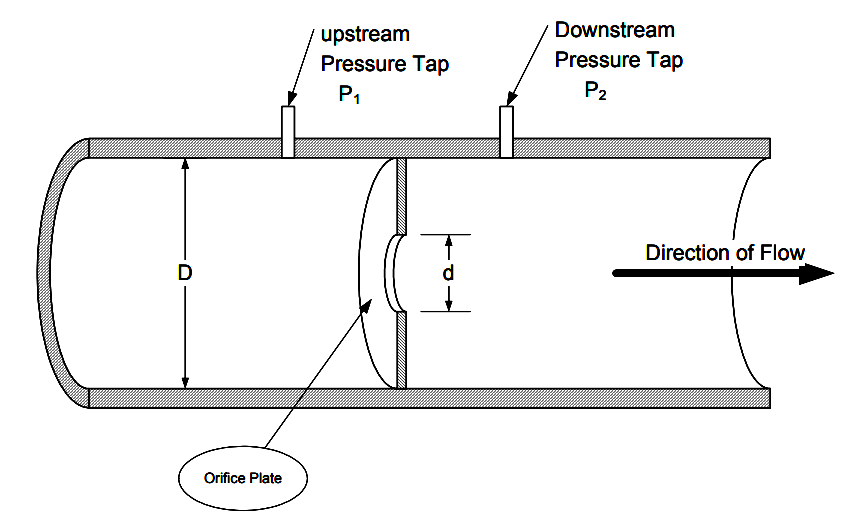

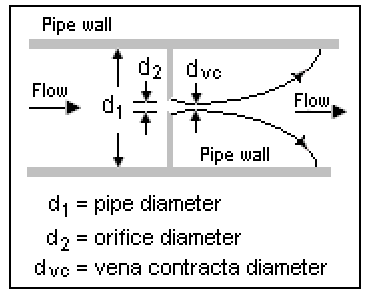

The equivalent of the notch weir in a tube would be an orifice plate. This flow device is created by inserting an obstructing plate, usually with a round hole in the middle, into the pipe and measuring the pressure on each side of the orifice. This is again a very simple device that has been in use for measuring both gas flow and liquid flow for decades.

These plates are generally installed by trapping it between two pipe flanges. Pressure taps on each flange allow you to easily measure the pressure differential across the plate. This pressure differential, along with the dimensions of th are combined with certain fluid properties to determine the flow through the pipe.

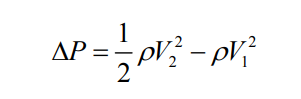

The calculation for incompressible (liquid) flow is described by the incompressible Bernoulli equation, as long as the flow is sub-sonic ( < mach 0.3).

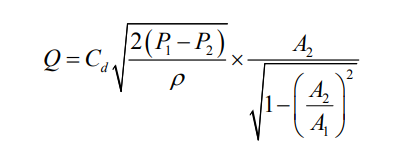

Given the following physical layout, you can modify this formula to take into account the dimensional information rather than the velocity. Also the equation above assumes perfectly laminar flow, which is generally not th in the real world. Flows in pipe will have a certainly amount of turbule which acts to convert kinetic flow energy into heat. This effect is taken into account by adding a new term to the equation called a discharge coefficient (Cd ). The resulting equation shows how th area and this new coefficient are applied to get a flow rate (Q).

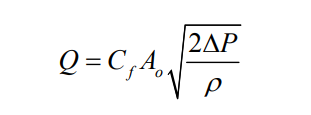

Since the actual flow profile at location 2 (downstream) is quite complex, making the effective value of A2 uncertain, a substitution is made and a new coefficient Cf is put in place of the area and Cd. The new equation looks like:

As you can see the formula has been simplified significantly, now only requiring the value of Cf, the area of the orifice (Ao), the density of the fluid and the differential pressure to obtain the volumetric flow rate. The only problem now is the value of Cf.

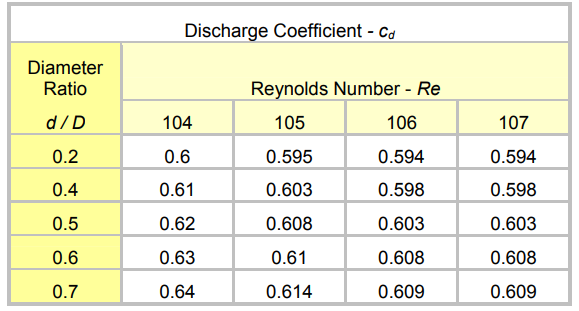

The flow coefficient is found experimentally and is tabulated in numerous reference books. This value ranges from 0.6 to 0.9 for most orifices, and the value depends on the orifice and pipe diameters as well as the Reynolds Number.

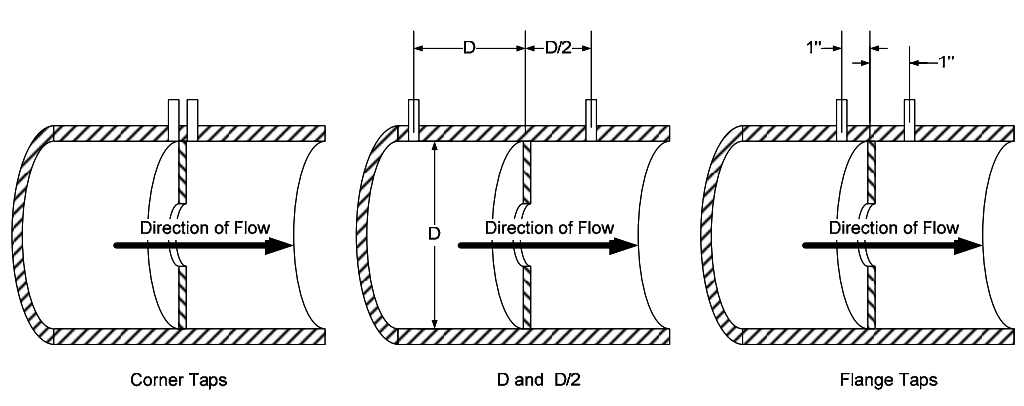

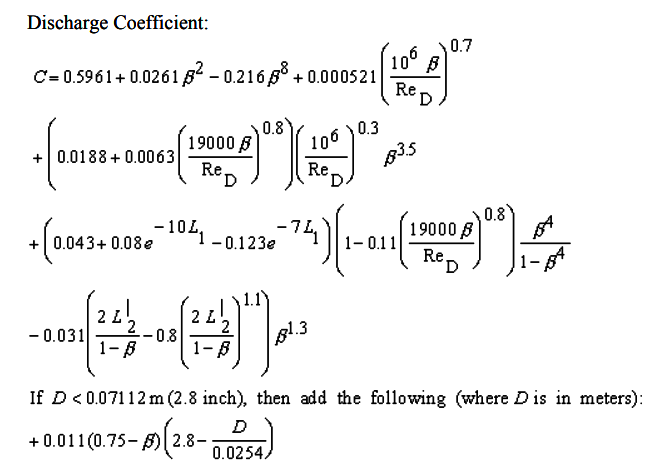

This takes care of the incompressible flow, but what about compressible flow, such as air. In this case the orifice flowmeter becomes much more difficult to calculate. The placement of the pressure taps even effect the calculations.

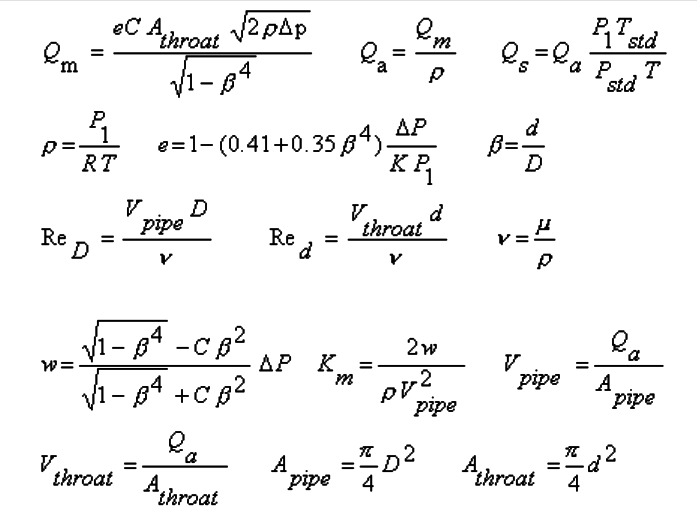

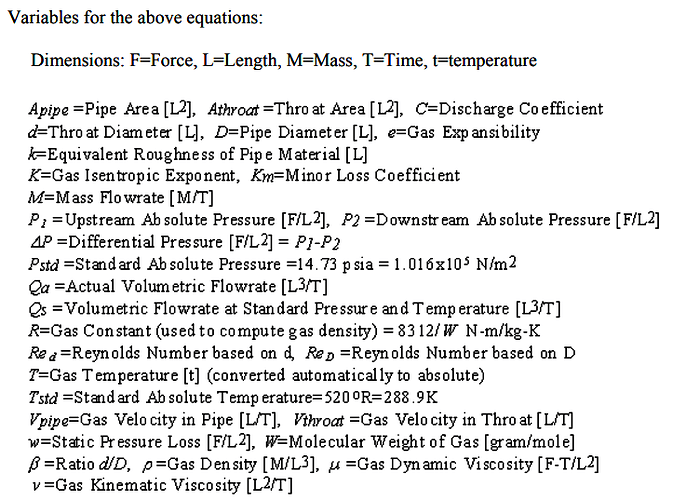

Without going into detail here are the equations for calculating the flow for a gas in pipes larger than 5CM in diameter. These are based on ISO 1991 and 1998.

Corner Pressure Taps: L1 = L’2 = 0

D and D/2 Pressure Taps: L1 = 1 and L’2 = 0.47

Flange Pressure Taps: L1 = L’2 = 0.0254/D where D is in meters

The primary disadvantage of the orifice type flow meter is that there is a significant pressure drop across the plate, which is not recoverable.

For this reason selection of this meter must only be used where you can afford the pressure drop without affecting the rest of the system operations. This is also the reason that the next flow meter type was developed.

Credits - Mitchell Cottrell