An overload relay has two basic parts:

- A heater element that is connected in series with the power line to the motor. All current drawn by the motor must pass through the heater element.

- A set of normally closed contacts that are connected in series with either the lines feeding the motor (manual starters) or the coil of the magnetic contactor (magnetic starters). The types of relays most commonly seen are the bimetallic strip and the melting-solder pot assembly.

Bimetallic Strip

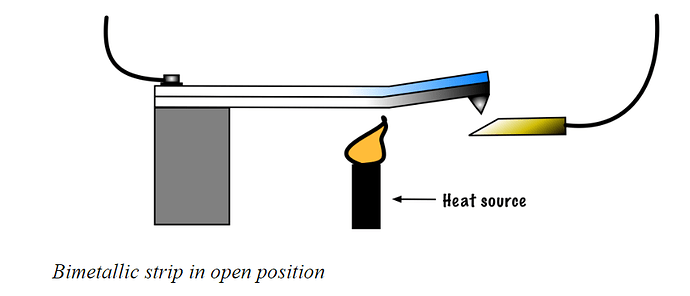

The bimetallic strip consists of two dissimilar metals with different heating coefficients. As they heat, they expand at different rates, which causes them to bend or deform at a preset temperature. This bending action can open or close a set of contacts.

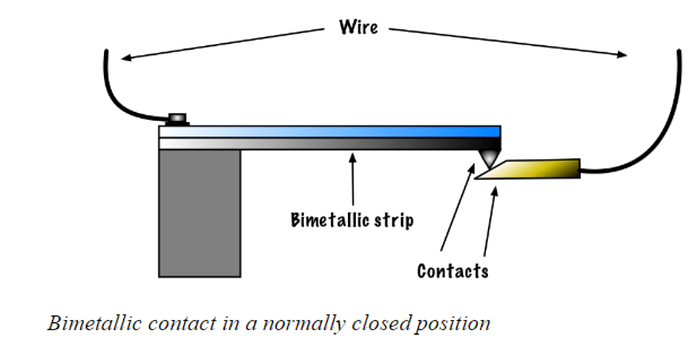

When used in an overload device, the bimetallic strip is mechanically linked to a set of normally closed electrical contacts. When an overload occurs, the bending action opens the set of normally closed contacts, interrupting the current to the circuit

Here the normally closed contacts are allowing current to pass through them, while the heat source is beginning to deform the metal.

The heat source has caused the grey-shaded metal (the piece on the bottom) to expand faster than the blue-shaded metal (the piece on the top) and so has opened the set of normally closed contacts, thus interrupting the current flow to the motor.

Melting Solder Pot

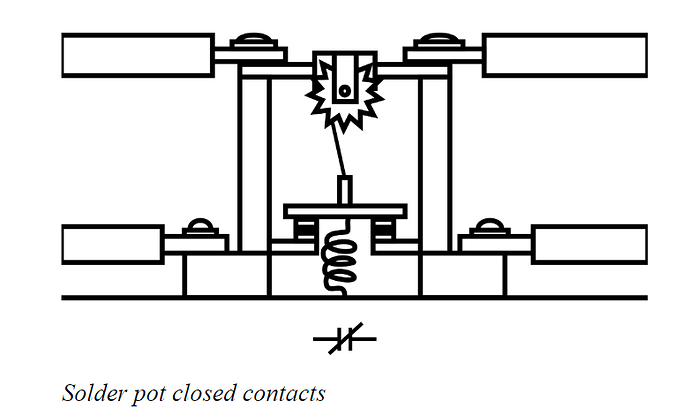

The melting solder pot consists of a heater element, a solder-pot assembly, ratchet wheel, and a set of normally closed contacts.

A spring is held under tension by the ratchet wheel. If the wheel is allowed to spin, then the spring will push upwards and open the set of normally closed contacts. The wheel is held in place by the solder inside the solder-pot assembly. Different levels of tin and zinc in the solder change the melting temperature, allowing for use at many different current ratings and ambient temperature settings.

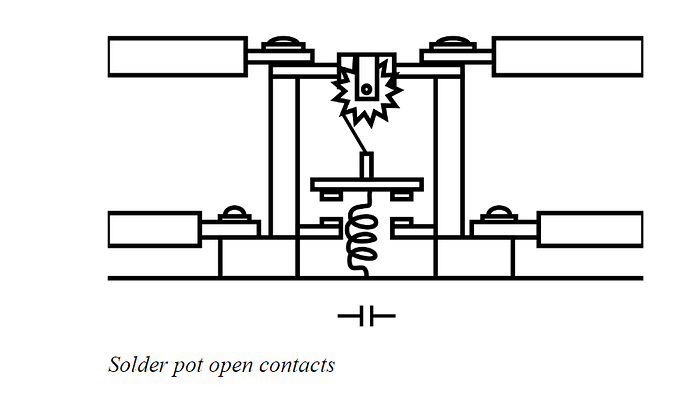

If an overload current is sensed by the heater elements for too long a time, then the alloy becomes a liquid, allowing the spring to push open the normally closed contacts. This causes the line contacts to trip open and interrupt current flow to the motor.

Both the bimetallic strip and melting solder-pot rely on thermal energy to trip their elements. As such, a cool-down period is required before the contacts can be reset. Once the relay cools, the bimetallic strip will return to its normal position, or the melted solder will solidify and the ratchet wheel can be reset to close the line contacts again.

Other Types of Overload Relay

Some modern motor control systems incorporate real-time current transformer monitoring applications that use integrated computer control circuits to protect against motor overloads. These systems can be interconnected with networked PLC’s and other safety equipment.

Reference

Basic Motor Control by Aaron Lee and Chad Flinn is used under a CC BY 4.0 Licence.

.