When a three-phase motor is first energized, it experiences an inrush current and harsh starting torque. If, for example, a motor is spinning in the forward direction and is stopped and suddenly reenergized in the reverse direction before the shaft of the motor has time to come to a complete stop, the motor will be said to have been “plugged.”

Plugging is hard on motors, and if they are directly attached to high inertia loads, the shaft of the motor can shatter. Plugging also causes excess heating of the conductors that make up the coils inside the motor, as well as the power contacts of the motor starter. If a motor is expected to make sudden reversals of direction, then the motor starters should be increased in size and horsepower rating to accommodate for this more severe operation.

Some circuits use this plugging action to quickly decelerate and stop a motor. For example, in certain machine-tool operations where instantly stopping motor drives may be necessary. We will be examining a plugging circuit in greater detail further in this text.

If the sudden reversal of a motor is considered undesirable, then our control circuit can be designed to provide anti-plugging, which can be provided by either a normally closed zero-speed switch or off-delay timer relays.

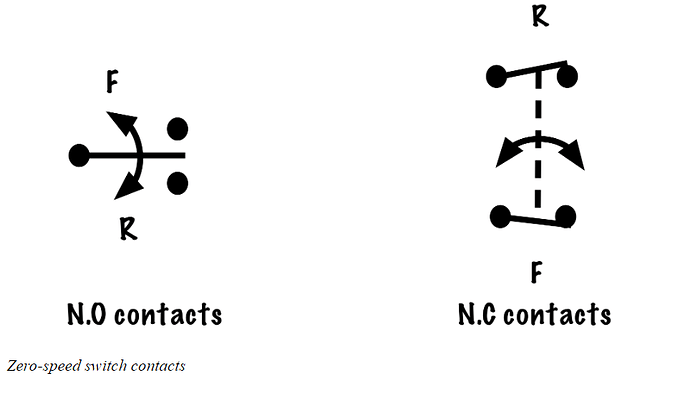

As a general rule, the control scheme for plugging includes a reversing magnetic starter and a rotary-motion switch called a zero-speed switch. The switch assembly is usually connected directly to the shaft of the motor or the driven equipment so that when the motor spins in a particular direction, the contacts change their state (normally closed contacts open, and normally open contacts close).

Normally open contacts provide plugging while normally closed contacts provide anti-plugging.

Reference

Basic Motor Control by Aaron Lee and Chad Flinn is used under a CC BY 4.0 Licence.