Hello

when we need to use Profibus PA junction box ?

I have 8 flow indicator transmitter far away from PLC about 90m , all the instruments are communicating with profibus

do we need to use junction box in such case ?

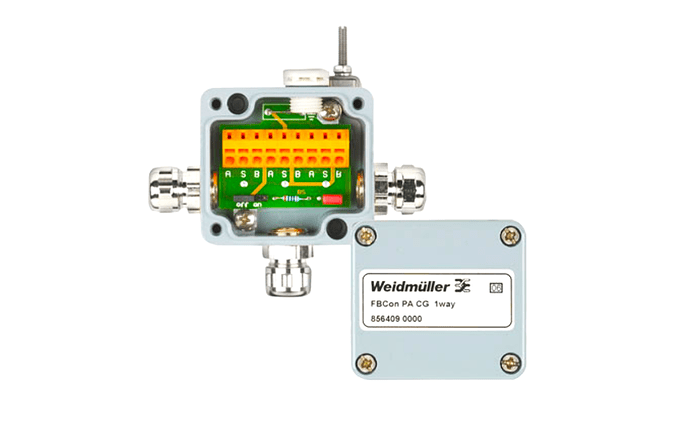

A Profibus PA junction box is used to connect multiple Profibus PA devices (like your flow indicator transmitters) to a single Profibus cable, simplifying the network topology and reducing the amount of cabling required.

Profibus PA junction box

In your case, with 8 flow indicator transmitters located 90m away from the PLC, a junction box could be beneficial. Here’s why:

- Simplified Wiring: Instead of running individual cables from each transmitter to the PLC, you can run a single cable to the junction box, and then connect each transmitter to the junction box. This can significantly reduce the amount of cabling required.

- Easier Troubleshooting and Maintenance: With a junction box, it’s easier to isolate and troubleshoot issues with individual devices. If a device fails, it can be disconnected from the junction box without affecting the rest of the network.

- Scalability: If you need to add more devices in the future, it’s easier to do so with a junction box. You can simply connect the new device to the junction box, without having to run a new cable all the way back to the PLC.

Keep in mind that the use of a junction box should comply with the Profibus PA network design rules, including limits on the total network length, the number of devices, and the power requirements of the devices. Always consult with a qualified engineer or the device manufacturer if you’re unsure.

Remember that the junction box should be suitable for the environment in which it’s installed. For example, if the area is classified as hazardous, you’ll need to use a junction box that’s rated for use in hazardous areas.

Thank you for sharing your knoweldge

PLease another question, i have 8 motorized valve , that are connected with profibus DP ,

same distance too , do they need junction box , ?

Note that the 8 MOV’s are connected as daisy chain protocol ( redundant )

In a Profibus DP network, devices are typically connected in a daisy chain topology, where each device is connected to the next in a line. This is different from a star topology, where each device is connected individually to a central point (like a junction box).

In your case, with 8 motorized valves (MOV) connected in a redundant daisy chain, a junction box is not typically required. Here’s why:

- Daisy Chain Topology: In a daisy chain, each device is connected directly to the next. This eliminates the need for a junction box, as each device is not connected individually back to the PLC.

- Redundancy: In a redundant daisy chain, each device is connected to two others, providing a backup path for communication in case one connection fails. This further reduces the need for a junction box, as the network can continue to operate even if one device or connection fails.

There are some cases where you might still want to use a junction box in a Profibus DP network:

- Physical Layout: If the devices are physically arranged in a way that makes a daisy chain difficult (for example, if the devices are spread out in different directions), a junction box could help simplify the wiring.

- Maintenance and Troubleshooting: A junction box can make it easier to disconnect individual devices for maintenance or troubleshooting, without affecting the rest of the network.

The design of your Profibus DP network should comply with the Profibus network design rules, and you should consult with a qualified engineer or the device manufacturer if you’re unsure.

Thanks a lot