We can not use the raw water for the boiler operation. If raw water is used for the boiler operation it may cause scaling in the boiler tubes because the raw water contains hardness. So we need to treat the boiler water before entering the boiler. The water entered into the boiler is known as DM water (De-mineralized water). for this purpose, we need a DM water plant.

there are two types of plant generally incorporated. These are:

Demineralization plant ( DM plant )

Reverse Osmosis plant ( R O plant )

Demineralization plant (DM Plant) make use of a chemical method to separate out the dissolved salt in raw water. But reverse osmosis plant (RO Plant) make use of a simple physical method to separate the dissolved salts. Before feeding the raw water to DM & RO plants sand filtration is done by different filters.

Along with these two plants, a deaerator is also used. deaerator is used to remove the dissolved oxygen in the feed water. This dissolved oxygen reacts with the boiler tubes and corrosion can take place in the boiler tubes which can damage the boiler tubes.

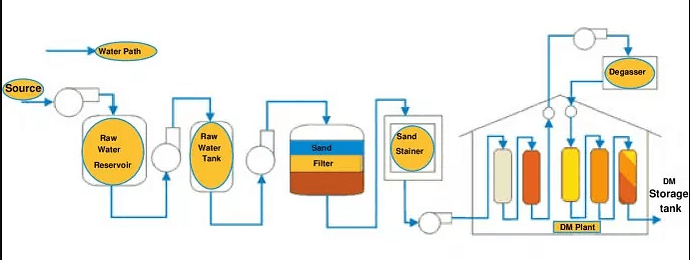

Complete arrangements and inside equipment of these plants are described below in the image given.

boiler feed water treatment plant

Demineralization Plant (DM Plant)

The function of the demineralization plant (DM Plant) is to remove dissolved salt by ion exchange method (chemical method) and thereby producing pure feed water for the boiler.

The salts which make the water hard are generally silicates, carbonates, bi-carbonates, chloride, and phosphates of calcium, potassium, sodium, iron, and magnesium.

three types of resin used for boiler feed water treatment process are-

Anion exchange resin

Cation exchange resin

Mixed Bed Resin

Resins are chemical substances and are used to react with salts and eliminate them by the chemical process.

Cation exchange resin exchanges the cations with the salts dissolved in hard-water.

![]()

Thus H2SO4, H2CO3 are also produced. We have removed Na+ but the water has become acidic.

Anion exchange resin, as the name suggests, exchanges anions with the salts dissolved in hard-water.

![]()

This way we have eliminated Cl- and thus acidity of the water. The similar reaction is for H2SO4 also.

DM plant

Mixed Bed Resins

These mixed bed resins are to remove the ions (especially Na+ and SO3^2-) which may further present in the water after the foregoing process of purification.

The function of the degasser tower is to remove carbonate ions by forming carbon-di-oxide. In degasser tower stream of water is poured from top and air is blown from bottom to top. In the pressure of air, the carbonic acid (H2CO3) present in the water dissociates into H2O and CO2.

This CO2 is free to mix with air.

Benefits of using degasser are:

- It saves the resins which are very costly chemicals and thereby improves the economy of the boiler feed water treatment process.

- It removes the carbonic acid and other gases mixed with water by the simple physical method and hence reduce the chances of corrosion.

- The H2CO3 free water is now collected in degasser sump and then pumped to anion exchange resin inlet.