IEC 60751:2008 is considered the international standard and specifies the tolerances for platinum RTD elements. The two most common tolerances for Pt100 RTD sensors are class A and Class B, for closer tolerance 1/3 DIN and 1/10 DIN standards are available.

The higher the element tolerance the broader it’s range to deviate away from the temperature-resistance curve increasing the level of uncertainty, although strictly speaking this doesn’t make 1/10th DIN detectors any more accurate then class B detectors, however it does significantly reduce uncertainty of reading.

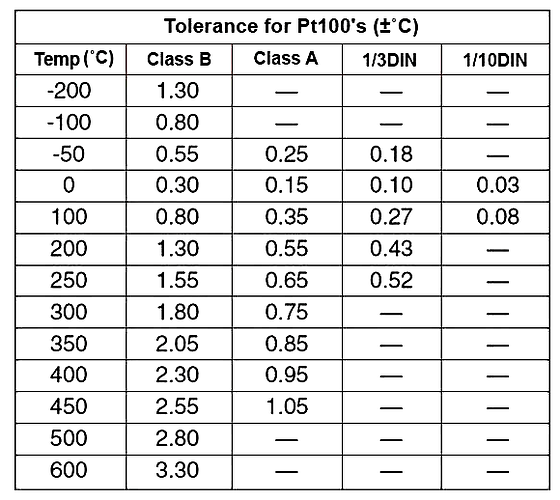

The table below shows the tolerance for class A and class B detectors as defined by DIN 43760, these standards are then used to find the tolerance of 1/3 DIN and 1/10 DIN detectors.

As you can see the tolerance of a class B detector is ten times higher than the tolerance of a 1/10 DIN detector meaning the uncertainty of reading in a class B detector is ten times higher than in a 1/10 DIN detector. It should be noted that tolerances defined in the table below only refer to bare detectors and do not account for the design or construction of the complete sensor.

Misinterpretation of tolerance can lead to unnecessary expenditure as people assume closer tolerance assures better accuracy.

Where the differences in uncertainty can be eliminated or significantly reduced a calibrated class B detector is more cost effective than 1/10 DIN detector for example if an RTD feeds into a process control system the characteristics of each individual sensor can be input eliminating the uncertainties identified in calibration.

Reference : sterlingsensors