Thermocouple works on the fact that when a junction of dissimilar metals heated, it produces an electric potential related to temperature.

As per Thomas Seebeck (1821), when two wires composed of dissimilar metals are joined at both ends and one of the ends is heated, then there is a continuous current which flows in the thermoelectric circuit.

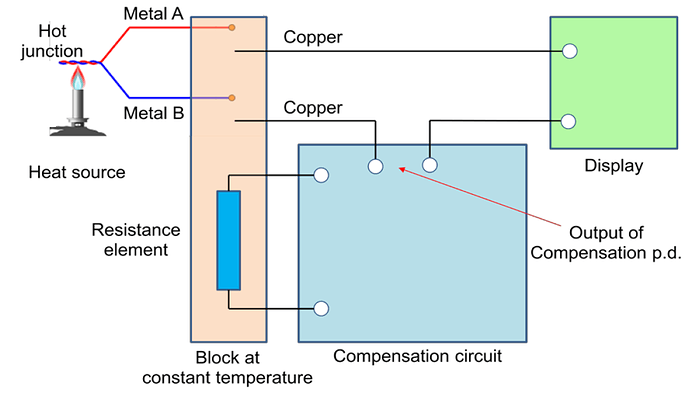

Schematic of Thermocouple Circuit

Figure shows the schematic of thermocouple circuit. The net open circuit voltage (the Seebeck voltage) is a function of junction temperature and composition of two metals. It is given by,

where α, the Seebeck coefficient, is the constant of proportionality.

Generally, Chromel (90% nickel and 10% chromium)–Alumel (95% nickel, 2% manganese, 2% aluminium and 1% silicon) are used in the manufacture of a thermocouple.

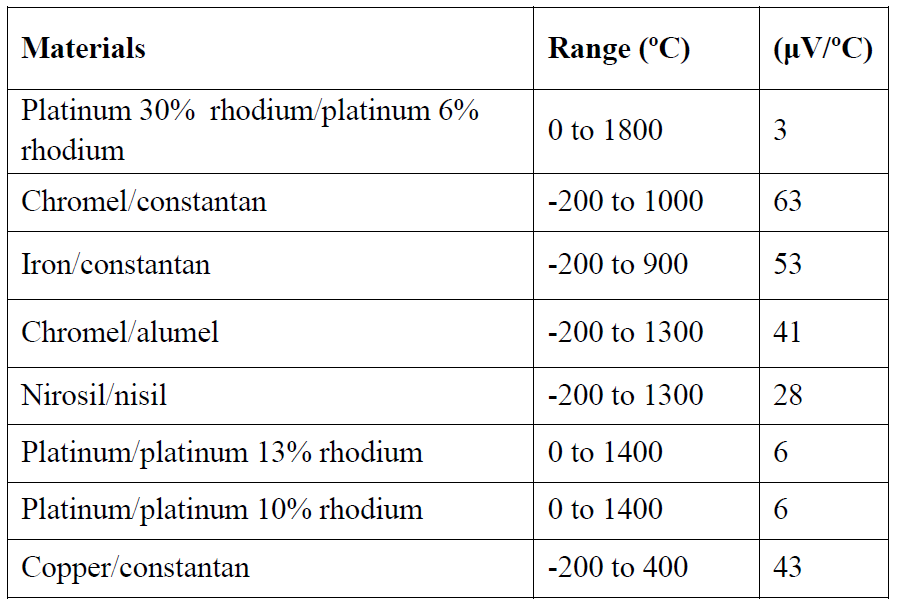

Table shows the various other materials, their combinations and application temperature ranges.

Thermocouple materials and temperature ranges

Applications of Thermocouples

- To monitor temperatures and chemistry throughout the steel making process

- Testing temperatures associated with process plants e.g. chemical production and petroleum refineries

- Testing of heating appliance safety

- Temperature profiling in ovens, furnaces and kilns

- Temperature measurement of gas turbine and engine exhausts

- Monitoring of temperatures throughout the production and smelting process in the steel, iron and aluminum industry