Could you share your insights on selecting an appropriate flow meter for flaring waste gas? I’m aware that thermal flow meters are quite sensitive to gas composition yet offer a favorable turndown ratio, and while ultrasonic meters have their own set of challenges, optical twin-rotors turbine flow meters also present a significant turndown ratio but are inherently volumetric.

I’m interested in understanding your experiences or recommendations in this context. Currently, a pitot meter is in place, but it fails to meet the high flow and extensive turndown ratio demands, prompting the need for a different insertion-type meter. The flow range in question spans from 600 kg/h under normal conditions to 245000 kg/h in fire scenarios. Ideally, I’m looking for a flow meter capable of directly measuring mass flow.

Flow meter for flaring

Selecting the right flow meter for waste gas to flare, especially in industrial settings, is crucial due to the variability in gas composition, the wide range of flow rates, and the need for accurate measurement under different scenarios. Here are some considerations based on industry practices and technological compatibility:

-

Thermal Mass Flow Meters: As you mentioned, thermal mass flow meters are sensitive to gas composition but are favored for their ability to measure the mass flow directly without needing separate temperature or pressure inputs. They have a good turndown ratio and are suitable for low-flow sensitivity. However, changes in gas composition can affect the accuracy, so they are often used where the gas composition is known and relatively constant or can be compensated for.

-

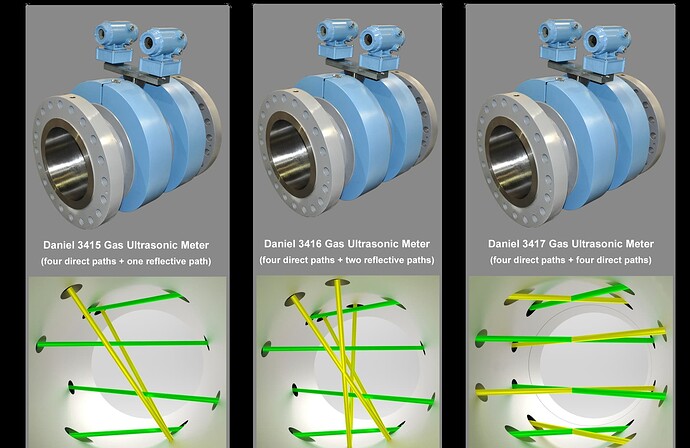

Ultrasonic Flow Meters: Ultrasonic flow meters are known for their high accuracy and wide turndown ratio. They are less sensitive to changes in temperature, pressure, and gas composition compared to thermal meters. However, they can be more expensive and might require a straight run of pipe for accurate measurement. They are often used in applications where the flow range is extensive, and low maintenance is desired.

-

Optical Twin-Rotors Turbine Flow Meters: These are less common but can be effective in measuring volumetric flow in large pipes and can handle high flow rates. They might require calibration for different gas compositions and typically have a good turndown ratio. However, being volumetric meters, they might not directly measure mass flow, which is a preference for your application.

-

Coriolis Mass Flow Meters: For direct mass flow measurement, Coriolis flow meters are highly accurate and provide direct mass flow, density, and temperature measurement. They are less affected by changes in the gas composition, temperature, or pressure. They can handle a wide range of flow rates and are suitable for various applications, including flare gas measurement. However, they can be expensive and might require more space and support due to their weight and configuration.

-

Differential Pressure Meters with Multi-Variable Transmitters: While traditional Pitot tubes might not handle the wide turndown ratio well, using a differential pressure meter with a multi-variable transmitter can improve performance. These systems can compensate for temperature and pressure changes and better handle varying flow conditions. They can be configured to provide mass flow readings and can be more adaptable to existing installations.