This article covers the Single-stage Pressure Regulator Principle, Single-stage Pressure Regulator diagram, operation, advantages & disadvantages.

High pressure gas from the supply enters into the regulator through the inlet valve. The gas then enters the body of the regulator, which is controlled by the needle valve.

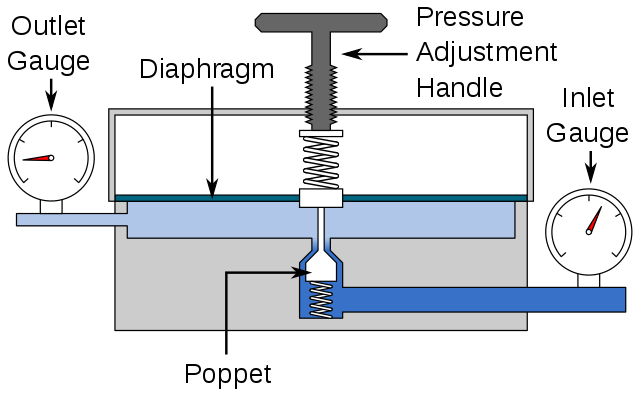

Single-stage Pressure Regulator

The pressure rises, which pushes the diaphragm, closing the inlet valve to which it is attached, and preventing any more gas from entering the regulator.

The outlet pressure and the inlet pressure hold the diaphragm/poppet assembly in the closed position against the force of the large spring.

If the supply pressure falls, it is as if the large spring compression is increased allowing more gas and higher pressure to build in the outlet chamber until an equilibrium pressure is reached.

Thus, if the supply pressure falls, the outlet pressure will increase, provided the outlet pressure remains below the falling supply pressure. This is the cause of end-of-tank dump where the supply is provided by a pressurized gas tank.

With a single stage regulator, when the supply tank gets low, the lower inlet pressure causes the outlet pressure to climb.

If the spring compression is not adjusted to compensate, the poppet can remain open and allow the tank to rapidly dump its remaining contents.

In other words, the lower the supply pressure, the lower the pressure differential the regulator can achieve for a given spring setting.

The outlet side is fitted with a pressure gauge. As gas is drawn from the outlet side, the pressure inside the regulator body falls.

The diaphragm is pushed back by the spring and the valve opens, letting more gas in from the supply until equilibrium is reached between the outlet pressure and the spring.

The outlet pressure therefore depends on the spring force, which can be adjusted by means of an adjustment handle or screw.