Pollutant emissions that must be measured and reported for regulatory compliance purposes are often required to be reported on a mass flow rate basis. Mass flow rates are typically calculated and reported in units of lbs or kg per hour and tons per year for pollutants such as CO, CO2, NO, NO2, total NOx, & SO2.

The pollutant mass flow rate is a function of the pollutant concentration of the stack gas, the stack size & shape, and the stack gas velocity.

The stack gas velocity can be determined in different ways such as ultrasonic meters, thermal dispersion meters, cross correlation meters, and Pitot tubes. Utilization of a Pitot tube is one of the most common, simple, and economical ways to determine stack gas velocity.

Calculating Velocity

Gas velocity is typically expressed in units of meters per second or feet per minute. The gas velocity calculation is a function of several variables including the differential pressure of the stack gas, the stack gas temperature, and the absolute stack gas pressure. A Pitot tube can be used to measure the stack gas differential pressure.

Using a Pitot Tube

The differential pressure measurement is performed using a Pitot tube that is connected to a pressure sensor with hoses. There are several types of Pitot tubes, so it is important to use the correct constant values and operating procedures for each Pitot tube. The following photo shows an S-type Pitot tube:

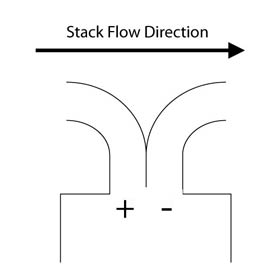

The S-type Pitot tube is inserted into the stack and rotated until the differential pressure measurement is greatest for a given location in the stack. The proper orientation is for the high pressure side of the S-type Pitot tube tip to face into the direction of the stack gas flow as shown in the diagram to the right.

For the most representative and accurate velocity values, multiple data points should be collected & averaged as the tip of the Pitot tube is traversed across the cross sectional area of the stack.