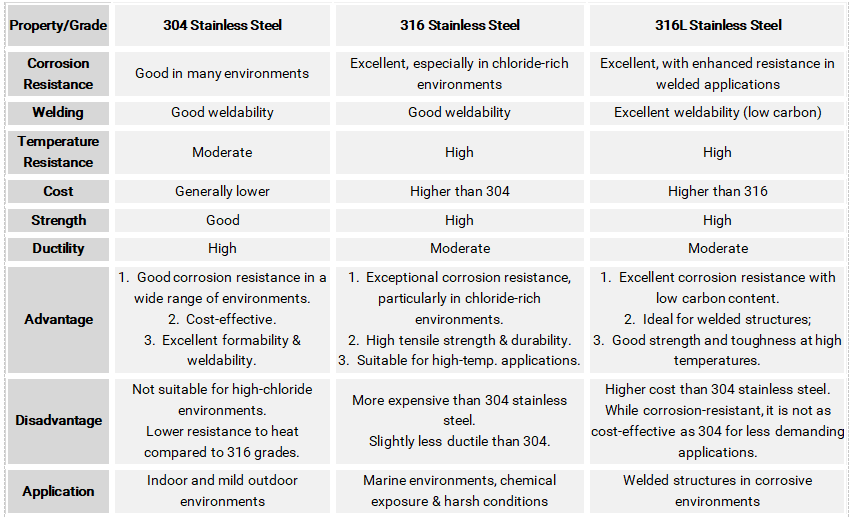

Stainless steel is a versatile material widely used across various industries because of its durability, corrosion resistance, and aesthetic appeal. Among the numerous grades available, 304, 316, and 316L are some of the most commonly used. Below, we’ll explore their differences.

304 Stainless Steel

304 stainless steel is an austenitic grade composed of approximately 18% chromium and 8%–10.5% nickel. This composition provides excellent corrosion resistance and good formability.

Renowned for its high tensile strength and oxidation resistance, 304 is suitable for a broad range of applications. However, it is less effective in chloride-rich environments compared to 316 grades.

316 Stainless Steel

316 stainless steel contains 16%–18% chromium, 10%–14% nickel, and 2%–3% molybdenum. The addition of molybdenum enhances its resistance to pitting and corrosion, particularly in chloride-exposed settings.

Often referred to as marine-grade stainless steel, 316 is ideal for harsh environments due to its superior corrosion resistance. It also boasts excellent welding and fabrication properties.

316L Stainless Steel

316L is a low-carbon version of 316 stainless steel. It has a similar composition but with a maximum carbon content of 0.03%.

The reduced carbon content minimizes the risk of carbide precipitation during welding, making 316L an excellent choice for welded applications. It maintains the same corrosion resistance as 316 but performs better in high-temperature environments.

304, 316, and 316L are commonly used as housing and sensor materials for sensors, flow meters, and other measuring instruments.

How to Select Between 314, 316 and 316L for Sensors and Flowmeters?