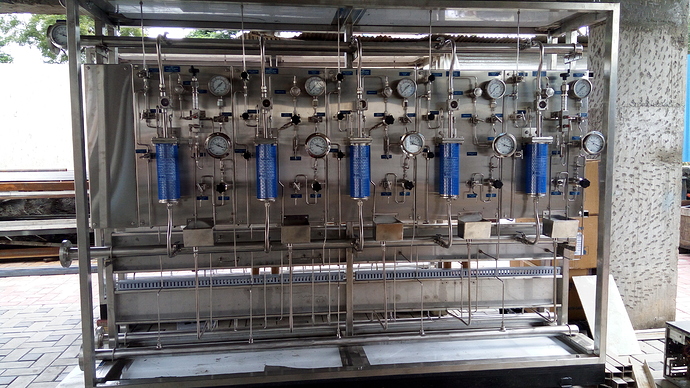

Steam and Water Analysis System (SWAS) is for continuous monitoring and control of water and steam purity in the plant cycle.

-

The sampling system obtains samples from steam and water system, which is adequately conditioned and fed to analyzers for continuous analysis with grab sample facility.

-

The analyzer outputs is used for providing –

-

Continuous monitoring of various parameters with isolated analog outputs of 4-20mA, DC for each parameter for monitoring in plant monitoring system. In safe area applications the analyzers are capable of operating on 110 V-120 V or 220V-240V AC power supply and give 4~20mA output, without any extra processing indicator. The analyzers are capable of withstanding sample temperatures up to 150 °C.

-

The Wet Panel is designed in such a way that it does not require any external source of power or air supplies for high temperature protections. This makes the wet system more reliable in all kind of environments i.e. safe as well as hazardous area. The system comes with sample conditioning devices and monitoring instruments (for temperature, pressure, flow & sample) and analyzers as well as all required accessories to provide a complete and integrated sampling and analysis system as per the intent and requirements of the customer.

-

All piping, tubing, fittings and other sample wetted parts in the sampling and analysing system is of type 316 stainless steel, except for those within the analyzers, which will be as per the catalogues provided.

-

All SWAS system components and accessories are from the latest proven product range of qualified manufacturers. We have in-house capabilities to manufacture the complete package which includes processes such as TIG welding, NDT procedures, Hydrostatic testing, and facilities for assembly & testing etc. The welding inside the SWAS panels is done by welders approved for high pressure welding.