Summary of Valve Types covers globe valve, needle valve, ball valve, gate valve, plug valve, check valve, butterfly valve, non-return valve, pressure relief valve.

Summary of Valve Types

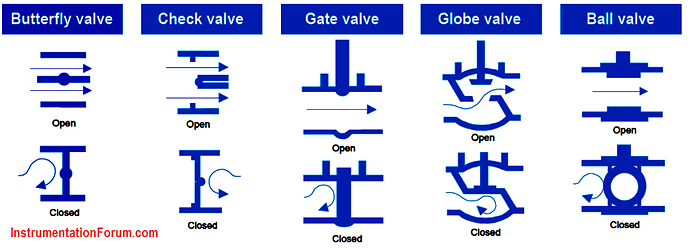

Globe valve

• Suitable for regulating flow

• Tight shut-off

• Pressure drop when open

• Used for high pressure clean fluids

Needle valve

• Suitable for regulating flow

• Fine control in small diameter piping

• Tight shut-off

• Used for clean fluids that have low flows

• High pressure drop when open

Ball valve

• Not suitable for regulating flow except in some specialized ball valves

• Tight shut-off

• Low pressure drop when open

• Used for gas, liquids or slurries

Butterfly valve

• Suitable for regulating flow

• Not suitable for tight shut-off

• Low pressure drop when open

• Used for low line pressure and large pipe line diameters

• Wide range of service: gas, liquids and slurries

Gate valve

• Not suitable for flow regulation, only suitable for on or off

• Tight shut-off

• Low pressure drop when open

Diaphragm valve

• Suitable for on/off or narrow range throttling control

• Tight shut-off

• Low pressure drop when open

• Used for corrosive fluids and slurries

Plug valve

• Suitable for regulating flow

• Tight shut-off

• Quick opening

• High pressure drop when open

Non-return valve

• Allow flow in one direction only

• Self closing

• Low pressure drop when open

• Not suitable for reciprocating pump discharge

Pressure relief valve

• Opens at pre-determined pressure level