If semiconductors or heat-treated metallic oxides (oxides of cobalt, copper, iron, tin, titanium, etc.) are used as the materials for producing temperature sensitive elements, then these temperature transducers are called thermistors (the name is derived from the term of ‘thermally sensitive resistor’).

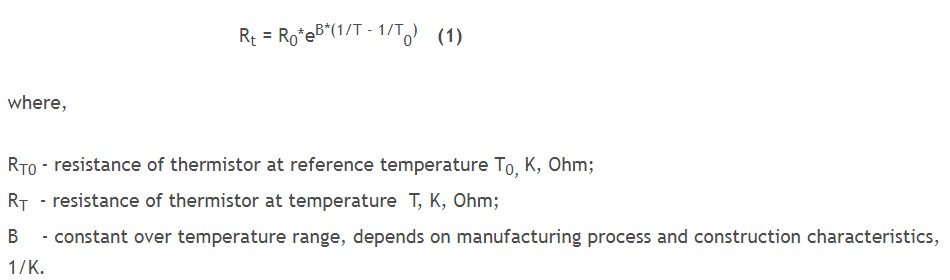

These oxides are compressed into the desired shape from the specially formulated powder. After that, the oxides are heat-treated to recrystallise them. As the result of this treatment the ceramic body becomes dense. The leadwires are then attached to this sensor for maintaining electrical contact.The following relationship applies to most thermistors:

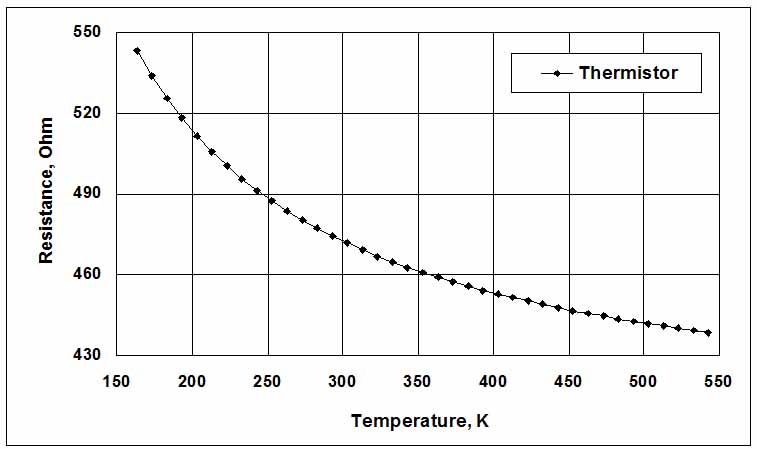

Fig. shows relationship between temperature and resistance for a thermistor.Thermistors have negative thermal coefficient of electrical resistance. It means that when temperature increases the electrical resistance of thermistor decreases. They have greater resistance change (this is an advantage) compared with RTD in a given temperature range. For example, if we compare what change in resistance will be caused by variation of temperature in 1 °C for Platinum and Copper RTD and for thermistor (see Fig. 2) in the temperature range from 273.15 to 423.15 K (ie, from 0 to 150 °C), we will obtain the following values:

• for platinum RTD - 0.38, Ohm / ̊C;

• for copper RTD - 0.04, Ohm / ̊C;

• for thermistor - 0.65, Ohm / ̊C;

Figure 2. Thermistor resistance vs temperature curve.

Wheatstone bridge and resistance measuring constant current circuits, similar to that used in the case of RTDs, are used for resistance measurement of thermistors. Despite their high sensitivity, thermistors have a worse accuracy and repeatability (this is the disadvantage) comparing with metallic RTDs.

Since the resistance vs temperature function for thermistors is non-linear (although, some modern thermistors have a nearly linear relationship of temperature vs resistance), it is necessary to use prelinearisation circuits before interacting with related system instrumentation. In addition, due to the negative thermal coefficient of electrical resistance an inversion of the signal to positive form is required when interfacing with some analog or digital instrumentation. Therefore, thermistors are not widely used in process instrumentation field, at least at present.

However, they have been well accepted in the food transportation industry, because they are small, portable and convenient. Another field of their growing application are heating and air-conditioning systems, where thermistors are used for checking the temperature in flow and return pipes.

All the discussed above instrumentation for temperature measurement refers to contact-type devices, because their sensitive elements are immersed in the measuring media. When dealing with temperatures above 1500 °C, contact-type temperature measuring devices are not applicable, because irreversible changes occur in metals which form their sensitive elements. It is possible to perform non-contact measurement of temperature by optoelectronic transducers.