Feed water flow to the drum should be continuous, failure of flow even for a brief period can cause serious and hazardous effect on the plant and operating personnel.

Many of the modern boilers today operate at steam temperatures near the maximum permissible metal temperatures and temperatures fluctuation as a result of poor feed water control can cause damage to the boiler tubes.

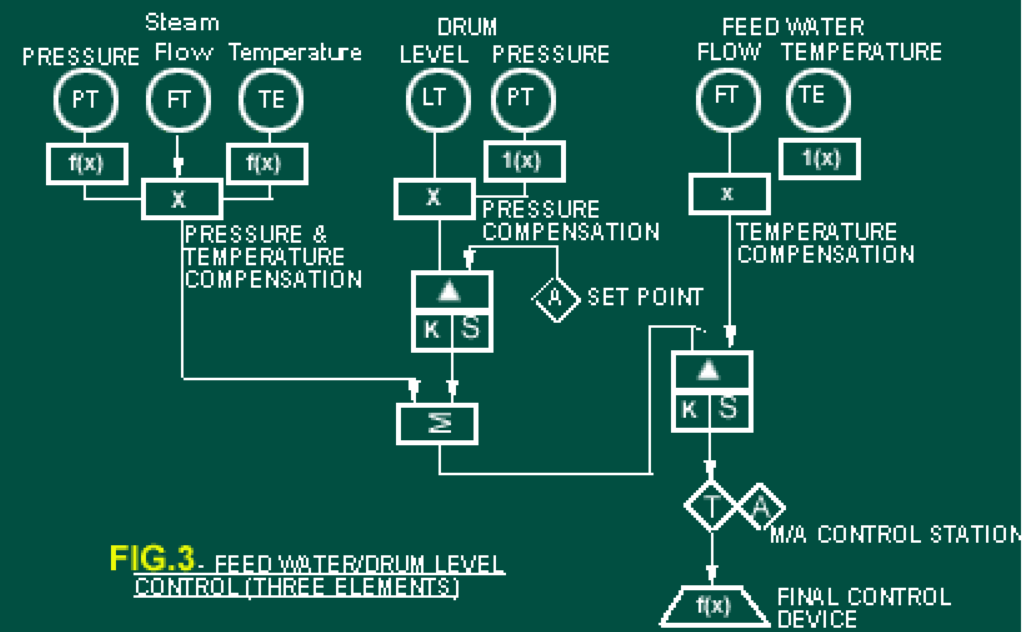

In the design of the boiler advantage is taken of the high level of performance achieved by high steam release to water ratio. This high ratio calls for a highly reliable water level control. The three elements employed are drum level, steam flow and feed water flow.

Three element system for drum level control

In this system (fig 3) the basic control is from the relation of the steam flow to feed water flow. In closed system, under normal steady conditions, with the drum level at the correct value, the ratio of steam flow to feed flow will be 1:1.

Any change in this condition will result in a control signal being applied to the feed water control valve. The signal from water level also will affect the readjustment of the feed water valve to trim the level back to its desired value, once stability is achieved.

Water flow measurement signal enters the control system to position the regulating valve in the feed water line so that the water input equals the steam output from the boiler.

Therefore any variations in feed water pressure ahead of the regulating valve, causing change in water flow will at once be detected by the flow meter and the regulating valve will react.

Source: Avant-Garde