The TK3 Calibration instrument simulates shaft vibration and position for calibrating Bently Nevada monitors.

It verifies the operating condition of the monitor readouts as well as the condition of the proximity transducer system.

A properly calibrated system means that the monitor readings and transducer inputs are accurate.

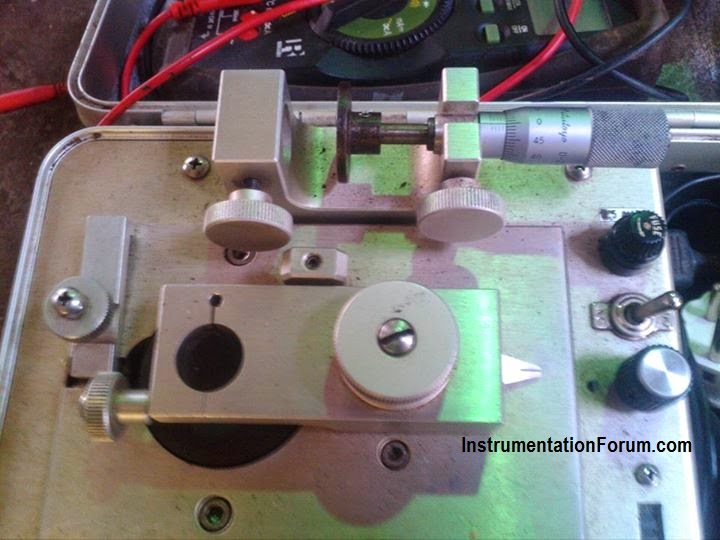

A spindle micrometer is used to check the transducer system and position monitor calibration. A probe mounting adapter provided with the TK3 holds the probe while the targt is moved toward or away from the probe tip in calibrated increments. The output from the proximitor sensor is recorded using a voltmeter.

Vibration monitors are calibrated using the motor-driven wobble plate to hold the proximity probe in place. The holder is located over the wobble plate to hold the proximity probe in place.

The holder and probe are adjusted to a position where the desired amount of mechanical vibration is found. The vibration is then measured using a dial micrometer that is supplied with the unit (no oscilloscope is needed).

A vibration monitor’s reading can then be compared to the known mechanical vibration signal input. The mechanical vibration signal from the TK3 can range from 50 to 254 micro meter (2 to 10 mils) peak-to-peak.