Chiller Types have been designed to cater to the diversified requirement of industrial chillers.Water chillers have evolved due to the variety in availability of type of energy at industry or small level.Types of chillers have made the use of the chillers flexible in terms of energy input.

Industrial research in the field of chiller has eased the selection of chillers in an economical and robust manner.There is no need of worry whatever type of energy you have available with you.

Each type of chiller targets the specific users classified on the basis of type of energy they have.

HVAC systems employ different types of chillers within the available resources of clients or users.

A chiller may be the best option for particular application while the same chiller may costly or less feasible for another application or plant.

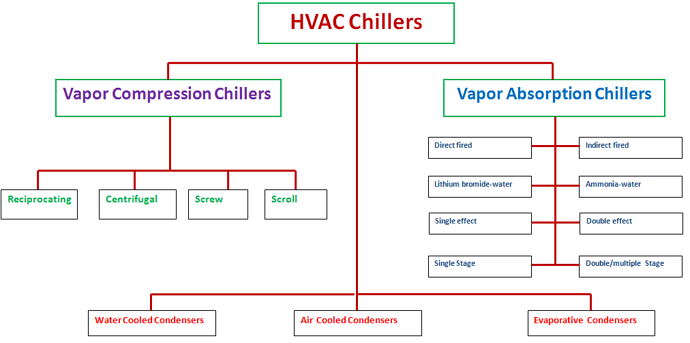

Hvac water chillers are classified primarily on the basis of cycle on which they work.

- Vapor compression chillers or compression chillers or electric chillers

- Vapor absorption chillers or absorption chillers or ammonia chillers or lithium bromide chillers

Vapor compression chillers are further classified on following basis.

- Type of compressor i.e reciprocating compressor,rotory compressor or screw compressor type vapor compressor chillers

- Type of condenser i.e air cooled condenser or air cooled chillers OR water cooled condensers or water cooled chillers

While Vapor absorption chillers are further classified as following:

- Direct fired absorption chillers (Natural gas, Diesel or Kerosene Oil Operated)

- Indirect fired absorption chillers