Pyrometers, powerful devices designed to measure high temperatures from a distance, are critical tools across a diverse range of industries. Their technology, which combines physics, optics, and electronics, has evolved significantly over the years, offering a fascinating insight into the broader trajectory of scientific progress. This article delves into the intricacies of pyrometers, from their fundamental principles to their wide array of applications.

1. Introduction to Pyrometers

1.1 Definition and Purpose

A pyrometer is a type of remote-sensing thermometer used to measure temperature. It does so without direct contact, making it ideal for extremely hot or molten substances. Originally, the term ‘pyrometer’ referred to a device that measured temperatures by detecting the thermal radiation of a heated object. However, the term has since expanded to include any device that measures high temperatures remotely.

1.2 History of Pyrometers

The concept of the pyrometer dates back to 1730 when the first rudimentary pyrometer was designed by Josiah Wedgwood, an English potter and industrialist. This device, called a pyrometer of fuel, was used to monitor the temperature inside a kiln.

Modern pyrometers, however, have come a long way since their early days. Advances in optics, sensor technology, and digital processing have led to their increasing precision and broadening applications.

2. Types of Pyrometers

2.1 Optical Pyrometers

Optical pyrometers operate by measuring visible light, which corresponds to a specific temperature range. The user aligns the device with the target object and adjusts a filament’s brightness within the pyrometer. When the brightness of the filament matches the brightness of the target object, the temperature is read off the pyrometer.

2.2 Infrared (IR) Pyrometers

Infrared pyrometers, also known as radiation or radiometric pyrometers, measure the infrared radiation emitted by an object. The radiation detected is directly proportional to the temperature of the object. This type can be further broken down into two categories:

- Single-color infrared pyrometers measure infrared radiation at a single wavelength. They require knowledge of the emissivity of the material to provide an accurate reading.

- Ratio or two-color infrared pyrometers measure the emitted radiation at two different wavelengths. This type provides a more accurate temperature measurement as it accounts for changes in emissivity and reduces errors due to dust, smoke, or partially blocked sight paths.

2.3 Fiber Optic Pyrometers

Fiber optic pyrometers are a newer variant designed to measure temperature in harsh or electromagnetic environments where conventional pyrometers cannot operate. They use a fiber optic cable to transmit radiation to a detector.

3. How Pyrometers Work: The Principle of Planck’s Law

The fundamental principle governing the operation of a pyrometer is Planck’s Law of Black-Body Radiation. This law states that all objects emit electromagnetic radiation when heated. The wavelength and intensity of this radiation are directly related to the object’s temperature.

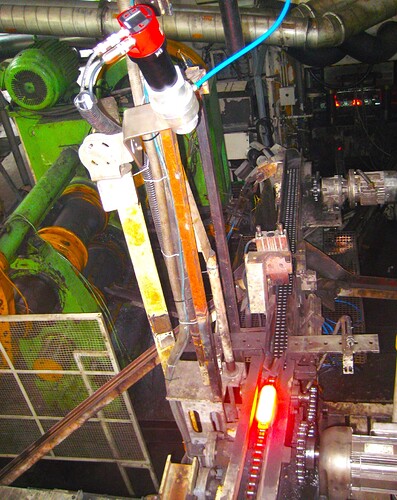

Image Courtesy: Ametek Land

A pyrometer works by detecting this radiation and converting it into an electrical signal, which can then be translated into a temperature reading. The emissivity of the object, its ability to emit infrared energy, also plays a significant role in obtaining accurate measurements.

4. The Factors Influencing Pyrometry

4.1 Emissivity

Emissivity is one of the most critical factors affecting a pyrometer’s reading. It’s a measure of a material’s efficiency in emitting thermal energy. Different materials have different emissivities, which can lead to variations in temperature measurements.

4.2 Distance and Size

The distance between the pyrometer and the object, as well as the size of the object, can impact the temperature reading. If the object is too small or too far away, the pyrometer may pick up radiation from surrounding surfaces and provide an inaccurate measurement.

4.3 Ambient Temperature

The ambient temperature can also influence the performance of a pyrometer. If a pyrometer is used in an environment much hotter or colder than its calibration setting, it can affect the accuracy of the readings.

5. Applications of Pyrometers

Pyrometers find application in a myriad of industries and sectors:

5.1 Industrial Manufacturing

In industrial manufacturing, pyrometers are used for temperature monitoring in various processes, including forging, casting, welding, and annealing. They help ensure that materials are heated to the correct temperature for optimum performance.

5.2 Glass Industry

In the glass industry, pyrometers are used to monitor the temperature of molten glass, facilitating high-quality and consistent production.

5.3 Semiconductor Manufacturing

In the semiconductor industry, pyrometers are critical for temperature control during the crystal growth process, which can significantly affect the quality of the end product.

5.4 Medical Industry

In the medical industry, pyrometers are often used in the form of ear or forehead thermometers. These devices offer a non-invasive way to measure body temperature quickly and accurately.

5.5 Food Processing

In the food industry, pyrometers help to ensure that food is cooked at the correct temperature, aiding in food safety and quality control.

6. The Future of Pyrometers

As technology advances, pyrometers continue to evolve, becoming more accurate, reliable, and easier to use. Future developments may include improvements in sensor technology and digital processing capabilities, leading to even more precise temperature measurements. We might also see a rise in smart pyrometers that can connect to the internet and provide real-time data for more efficient and effective temperature control.

7. Conclusion

In conclusion, pyrometers play a crucial role in numerous fields and industries, and their importance cannot be overstated. Understanding the principles behind their operation and the factors influencing their performance can help users harness their full potential and ensure accurate and reliable temperature measurements.