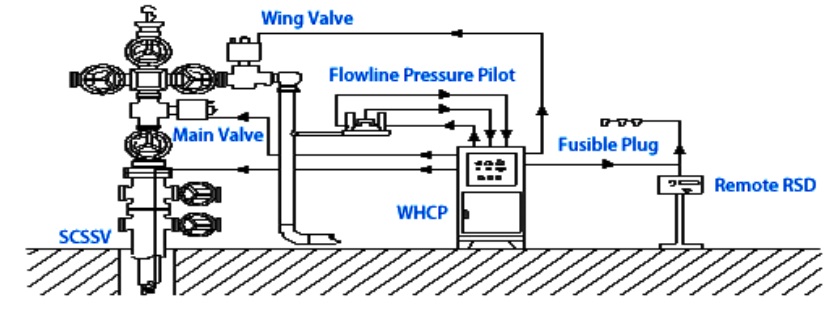

The below details the basic Wellhead Control Panel Functions, Wellhead Control Panel Parts like Hydraulic Power Unit, Control Module, Hydraulic Line, Enclosure.

Wellhead Control Panel Functions

Composed of WHCP

Hydraulic Power Unit :

- Field actuators up to the requested pressure.\

- Composed by Oil Reservoir, Pumps, Strainers, Accumulator.

- High Pressure: SCSSV

- Medium Pressure: SSV

Control Module (Production, Water Injection, Gas Injection) :

- Dedicated for one Well

- Hydraulic or Pneumatic Circuit (Sequence and Logic)

- Solenoid Valve, Manual Isolation Valve and Hydro Selector Valve, Pressure Switch, Pressure Gauge, Thermal Relief Valve, Check Valve, Isolation Balance Valve.

Hydraulic Line

- Pressure Regulator

Enclosure / Panel

- Control and Indication

- Junction Boxes

- Power Distribution, Motor Starter etc.

- Heating and Cooling Requirement

Wellhead Control System Single / Multi Well Control: For onshore and off shore applications.

- Control Options: Simple Pneumatic based control to completely automated solution with RTU/PLC based (SIL2 or SIL3) SIS.

- All electrical and electronic Controls: Designed to meet Explosion Proof, Flame Proof or Intrinsically Safe Hazardous requirements and certified by International authorities such as ATEX Directive, CENELEC, BASEEFA, UL, CSA etc.

- WHCP designed to meet environment at offshore, onshore and desert severe weather conditions

Function of WHCP

- Installation: near the well

- Control the Well: open or close the main shut off valve (SCSSV and SSV)

- By local Push Button on WHCP, activated from ESD, from F&G System or PSD.

- Input: ESD (PSD, PSHH, Fusible Plug) ESD PB.

- Output: Final Control Element, Signal Indicator (Local)

- Equipped with Recorder (Pressure, Temperature and Flow Rate.)

- Reset of the Panel: Manually.

Reference - http://new.hiscoi.com