Differential Head Flowmeters includes venturi, nozzle, and orifice meters. When properly installed and used, these meters have a potential accuracy of "1 percent.

These meters have no moving parts but use the principle of accelerating flow by some form of constriction. Heads are measured upstream where the meter is the size of the approach pipe and downstream where the area is reduced to a minimum.

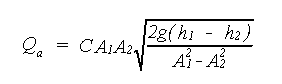

The velocity at one of these locations is solved for in terms of the difference of head between the two locations. Using the product of the upstream velocity and area results in discharge expressed as:

where:

Q a = discharge

A 1 = upstream approach area

A 2 = area of the throat or orifice opening

h 1 = upstream head measurement

h 2 = downstream head

g = gravity constant

C = coefficient determined experimentally

The term, h 1 - h 2, often written in shorter form as ![]() h , is the differential head that gives the name to this class of meters.

h , is the differential head that gives the name to this class of meters.

The values of the effective discharge coefficient in both of the equation forms, for the same differential flowmeter, are the same. The coefficients are the same because the area divided by the square root of the denominator in each equation has the same value.

Equation is valid for the venturi, nozzle, and orifice meters using proper respective effective coefficients. Each kind of flow meter has a different value of effective discharge coefficient.

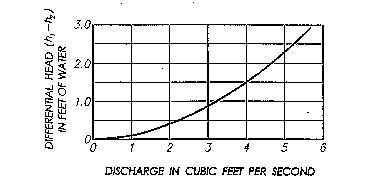

With differential flowmeters, the pressure difference between the inlet tap and the throat or minimum pressure tap is related to discharge in tables or curves using the suitable coefficients with the proper equation.

An example discharge curve is shown for an 8-inch (in) venturi meter on beolow figure. Thus, the meters may serve as reliable flow measuring devices.

Figure 1 – Typical calibration curve for an 8-in venturi meter - one kind of differential flowmeter.