Another temperature sensor often used in industry is the thermocouple. Among the various temperature sensors available, the thermocouple is the most widely used sensor.

What is a Thermocouple ?

Similar to the RTD, the thermocouple provides an electrical measurement of temperature.

Thermocouple Structure

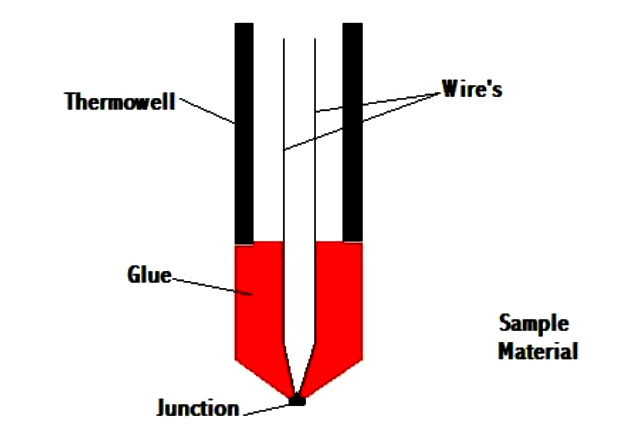

The thermocouple has a long, slender, rod-like shape, which allows it to be conveniently placed in small, tight places that would otherwise be difficult to reach. A schematic diagram of a typical thermocouple is shown in Figure 2.

Figure 2. Schematic Diagram of Thermocouple Structure

As illustrated in Figure 2, the thermocouple contains an outer sheath, or thermowell. The thermowell protects the contents of the thermocouple from mechanical and chemical damage. Within the thermowell lies two metal wires each consisting of different metals. Various combinations of materials are possible for these metal wires.

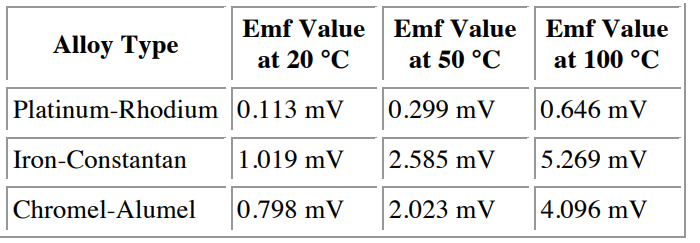

Three common thermocouple material combinations used for moderate temperature measurements are the Platinum-Rhodium, Iron-Constantan, and Chromel-Alumel metal alloys. The metal alloys chosen for a thermocouple is based upon the emf value of the alloy pair at a given temperature. Sample emf values for the most common materials at various temperatures are shown in Table 2.

For a given pair of materials, the two wires are connected at one end to form a junction. At the other end, the two wires are connected to a voltage measuring device. These ends of the wires are held at a different reference temperature.

Table 2. Common Metal Temperature and Emf Values

Various methods are used to maintain the reference temperature at a known, constant temperature. One method consists of placement of the reference junction within either an ice bath or oven maintained at a constant temperature. More commonly, the reference temperature is maintained electronically.

Though not as stable as an ice bath, electronically controlled reference temperatures are more convenient for use. Reference temperatures could also be maintained through temperature compensation and zone boxes, which are regions of uniform temperature.

The voltage difference across the reference junction is measured and sent to a computer, which then calculates the temperature with this data.

Thermocouple Operation

The main principle upon which the thermocouple function is based on is the difference in the conductivities of the two wire materials that the thermocouple is made of, at a given temperature.

This conductivity difference increases at higher temperatures and conversely, the conductivity difference decreases at lower temperatures. This disparity results in the thermocouples being more efficient and useful at higher temperatures.

Since the conductivity difference is small at lower temperatures and thus more difficult to detect, they are inefficient and highly unreliable at low temperatures. The conductivity difference between the two wires, along with a temperature difference between the two junctions, creates an electrical current that flows through the thermocouple.

The first junction point, which is the point at which the two wires are connected, is placed within the medium whose temperature is being measured. The second junction point is constantly held at a known reference temperature. When the temperature of the medium differs from the reference temperature, a current flows through the circuit.

The strength of this current is based upon the temperature of the medium, the reference temperature, and the materials of the metal wires. Since the reference temperature and materials are known, the temperature of the medium can be determined from the current strength.

Error associated with the thermocouple occurs at lower temperatures due to the difficulty in detecting a difference in conductivities. Therefore, thermocouples are more commonly used at higher temperatures (above -125°C) because it is easier to detect differences in conductivities. Thermocouples are operable over a wide range of temperatures, from - 200°C to 2320°C, which indicates its robustness and vast applications.

Thermocouples operate over this wide range of temperatures, without needing a battery as a power source. It should be noted that, the wire insulation might wear out over time by heavy use, thus requiring periodical checks and maintenance to preserve the accuracy of the thermocouple.

To determine the temperature of the medium from the current strength, the emf or voltage values of the current and of the wire materials at the reference temperatures must be known. Often, the measured temperature can be found by using standard thermocouple tables.

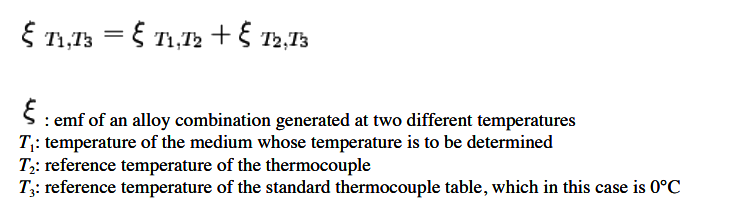

However, these tables are often referenced at 0°C. To correct for this different reference temperature, equation (3) can be used to calculate the temperature from a given current.

Once the emf between two alloys is calculated relative to a reference temperature when T3 is 0°C, the standard thermocouple table can be used to determine the temperature T1 of the medium. This temperature is usually automatically displayed on the thermocouple.

Apart from the common occurrence of the thermocouples being placed in the fluid to measure temperature change, thermocouples can be also embedded in solids with excellent results. This is highly effective while establishing the different thermal properties for a solid.

The heat transfer to the thermocouple will now be in the form of conductive heat transfer. As a result, this setup would be very similar to heat conduction in series, since the thermocouple is almost always made from a different material then the actual solid.

Such discrepancies depend on the manner in which the thermocouple is embedded in the solid and should be taken into account when the thermal properties are being calculated and analyzed.

One example is shown in the photo below.

Figure 3. Schematic diagram of how the thermocouple function