What is An Absorption Chiller ?

An Absorption Chiller is a machine uses a heat source to generate chilled water rather than electrical source that is used in vapor compression cycle.

It’s an attractive idea to produce chilled water with heat.

As the same in vapor compression cycle, absorption cycle achieve removing heat using the evaporation of a refrigerant at low pressure and the ejection of heat using the condensation the refrigerant at high pressure.

The major difference between a vapor compression system and an absorption chiller is that a vapor compression system using a compressor to make the pressure difference required to circulate the refrigerant while the absorption chiller using heat.

The absorption chiller is very attractive because using energy in the form of heat, such as solar or waste heat, makes it using a little work input and saving in money. Also it can works with industrial waste heat streams.

Why Do We Use Absorption Chiller ?

Vapor compression systems use a high grade of energy input to drive a compressor, so it consumes a lot of electricity. This also leads to more releasing of CO2 emissions. While the absorption chillers use a low grade of energy to generate a cooling effect. So we don’t have to use electricity but we can use any other heat source.

Absorption chiller also have other advantages like silent operation which is not compared with other systems.

Comparison Between Absorption Refrigeration Cycle and Vapor Compression Cycle:

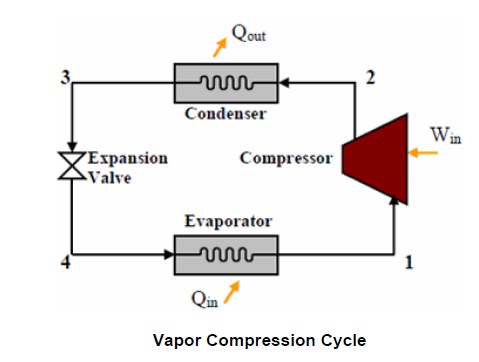

The vapor compression cycle basically consists of an evaporator, condenser, throttling valve, and a compressor. Figure below illustrates the components and flow arrangement for it.

In the shown cycle, refrigerant in the form of a cool mixture of liquid and vapor centers the evaporator at low pressure (4). Then using relatively warm air or water, the liquid refrigerant will boil. The resulted vapor (1) is pumped by the compressor, which raises refrigerant vapor pressure and temperature.

This hot refrigerant vapor at high pressure (2) enters the condenser, where heat is released to a lower temperature ambient air or water, and the refrigerant vapor turns into a liquid, then passes to the expansion device (3), where the pressure of the refrigerant is reduced to the pressure of the evaporator, and a little amount of the refrigerant boils, cooling the staying liquid refrigerant to the wanted evaporator temperature. Then mixture of the cool liquid and vapor refrigerant (4) passes to the evaporator and repeats the cycle.

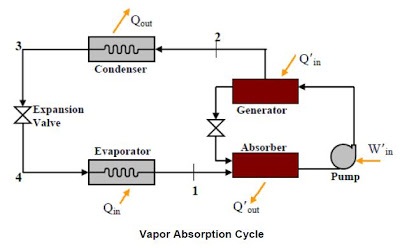

The absorption cycle is similar to the vapor compression cycle in many components, but it uses a different compression method and different refrigerants unlike the vapor compression cycle.The absorption cycle replaces the compressor with a generator, an absorber, and pump.

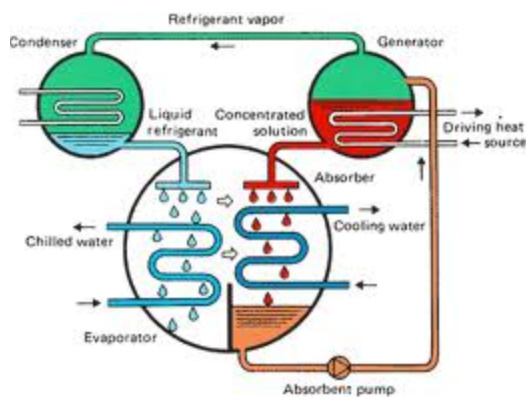

As we said, a refrigerant enters the evaporator at low pressure in the form of a cool mixture of vapor and liquid (4). Then the liquid refrigerant boils due to heat transferred from a relatively warm water to it. The function of the absorber is similar the suction side of the compressor, which the vapor refrigerant enters it and mixes with the absorbent.

The pump make the same process of the compressor, which pumps the mixture of absorbent and refrigerant to the generator at high pressure. In the generator, the refrigerant vapor is extracted and delivered to the condenser (2), where the refrigerant vapor condenses into a liquid due to heat transferred from it to lower temperature water.

Then the liquid refrigerant passes to the expansion device (3), where the pressure of the refrigerant is reduced to the pressure of the evaporator, and a little amount of the refrigerant boils, cooling the staying liquid refrigerant to the wanted evaporator temperature. Then mixture of the cool liquid and vapor refrigerant (4) passes to the evaporator and repeats the cycle.

Similarities between basic Vapor compression and Vapor absorption cycles:

- Both transfer heat between two fluids by circulating a refrigerant inside the chiller.

- Both have an expansion device to ensure the internal pressure difference, and a device to increase the refrigerant pressure.

- Condenser condenses the refrigerant vapor at low pressure and temperature by rejecting heat to the surroundings.

- By absorbing heat from the chilled water, the refrigerant vapor is evaporated at low temperature and pressure.

Differences between Vapor compression and Vapor absorption cycles

-

Unlike the vapor compression system, the absorption system achieves the cooling effect using heat energy in form of waste heat, steam, or direct fuel firing.

-

Vapor compression cycle uses compressor, but the absorption chiller system uses a liquid pump to produce the pressure difference between condenser and evaporator. A liquid pump is much easier in work and cheaper than compressing a gas, so that it takes less work input. However, the absorption chiller system replaces the compressor work input with a heat pump in the generator.

-

The absorption systems use different refrigerants that haven’t bad effect on environment, ozone depletion … etc. It uses –for example- lithium bromide as absorbent and water as the refrigerant.

-

The absorption chillers have very few moving parts compared to compression system, so they are less vibration and noise, requiring little maintenance. Also they are compact in large capacities.

-

The absorption chillers don’t depend very much on evaporator superheat, and are not affected by load variations.

-

The absorption chillers have a low operating cost due to using a low grade waste heat. But the coefficient of performance (cop=load/input) is lower compared to vapor compression system.