A bubbler level meter (air purge system or gas flushing system), provides a simple and inexpensive but less accurate (±1-2%) level measurement system for virtually any liquid, and typically for corrosive or slurry-type applications.

What is Bubbler Level Meter ?

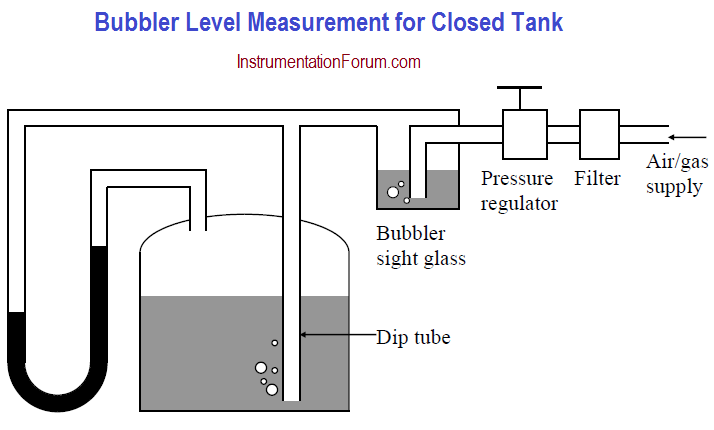

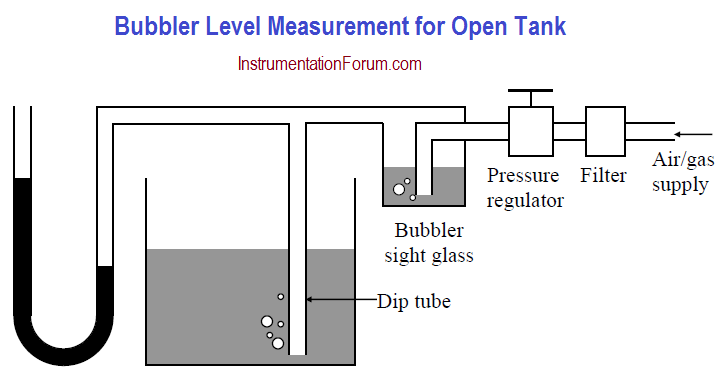

A constant flow of compressed air or an inert gas (usually nitrogen), is introduced through a dip tube. The pressure required to force bubbles through the tube at a constant rate (normally 60 bubbles per minute), is proportional to the hydrostatic pressure at the bottom end of the dip tube.

A bubbler sight glass, facilitate with adjusting the bubble rate. The level is determined from the difference between the bubbler pressure (back pressure) and the pressure at the surface of the liquid, by means of a DP transmitter or manometer.

Disadvantages of the bubbler system are

-

that the liquid’s density, influences measurement accuracy and

-

the need for compressed air or gas. The end of the dip tube may become plugged or clogged, and the dip tube is periodically purged (release of large amounts of air to clear the tube), to combat this situation.

Figures, depicts the measurement arrangement for an open tank and a closed tank respectively, using a u-tube manometer.