A second commonly used temperature sensor is the resistance temperature detectors (RTD, also known as resistance thermometer).

Unlike filled system thermometers, the RTD provides an electrical means of temperature measurement, thus making it more convenient for use with a computerized system.

An RTD utilizes the relationship between electrical resistance and temperature, which may either be linear or nonlinear. RTDs are traditionally used for their high accuracy and precision.

However, at high temperatures (above 700°C) they become very inaccurate due to degradation of the outer sheath, which contains the thermometer.

Therefore, RTD usage is preferred at lower temperature ranges, where they are the most accurate.

Resistance Temperature Detectors

There are two main types of RTDs, the traditional RTD and the thermistor. Traditional RTDs use metallic sensing elements that result in a linear relationship between temperature and resistance.

As the temperature of the metal increases, increased random molecular movement impedes the flow of electrons. The increased resistance is measured as a reduced current through the metal for a fixed voltage applied.

The thermistor uses a semiconductor sensor, which gives a power function relationship between temperature and resistance.

RTD Structure

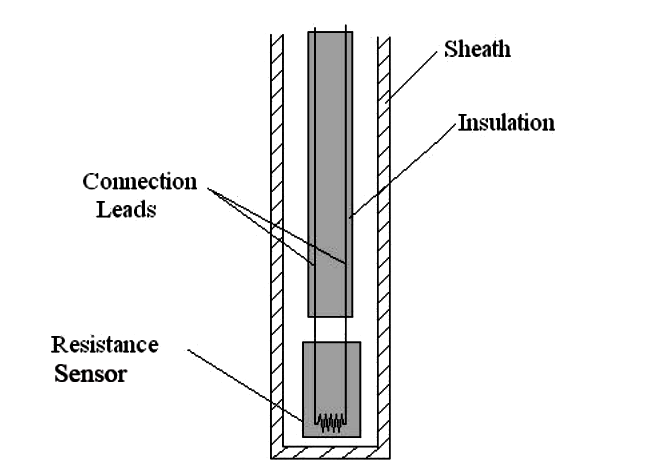

A schematic diagram of a typical RTD is shown in Figure 1.

Figure 1. Schematic Diagram of Resistance Temperature Structure

As shown in Figure 1, the RTD contains an outer sheath to prevent contamination from the surrounding medium. Ideally, this sheath is composed of material that efficiently conducts heat to the resistor, but resists degradation from heat or the surrounding medium.

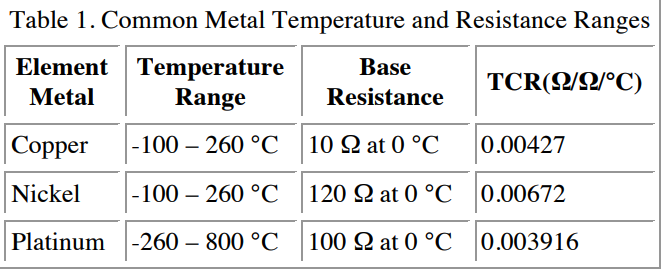

The resistance sensor itself is responsible for the temperature measurement, as shown in the diagram. Sensors are most commonly composed of metals, such as platinum, nickel, or copper. The material chosen for the sensor determines the range of temperatures in which the RTD could be used.

For example, platinum sensors, the most common type of resistor, have a range of approximately -200°C – 800°C. (A sample of the temperature ranges and resistances for the most common resistor metals is shown in Table 1). Connected to the sensor are two insulated connection leads. These leads continue to complete the resistor circuit.

There are 4 major categories of RTD sensors. There are carbon resistors, film thermometers, wire-wound thermometers and coil elements.

Carbon resisters are the most commonly used. They are inexpensive and are accurate for low temperatures. They also are not affected by hysteresis or strain gauge effects. They are commonly used by researchers.

Film thermometers have a very thin layer of metal, often platinum, on a plate. This layer is very small, on the micrometer scale. These thermometers have different strain gauge effects based on what the metal and plate are composed of. There are also stability problems that are dependent on the components used.

In wire-wound thermometers the coil gives stability to the measurement. A larger diameter of the coil adds stability, but it also increases the amount the wire can expand which increases strain and drift. They have very good accuracy over a large temperature range.

Coil elements are similar to wire-wound thermometers and have generally replaced them in all industrial applications. The coil is allowed to expand over large temperature ranges while still giving support. This allows for a large temperature range while decreasing the drift.

RTD Operation

Most traditional RTD operation is based upon a linear relationship between resistance and temperature, where the resistance increases with temperature.

For this reason, most RTDs are made of platinum, which is linear over a greater range of temperatures and is resistant to corrosion. However, when determining a resistor material, factors such as temperature range, temperature sensitivity, response time, and durability should all be taken into consideration.

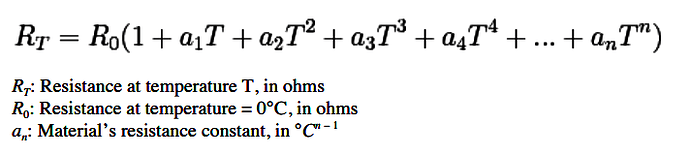

Different materials have different ranges for each of these characteristics. The principle behind RTDs is based upon the Callendar – Van Dusen equation shown below, which relates the electrical resistance to the temperature in °C.

This equation is merely a generic polynomial that takes form based upon experimental data from the specific RTD. This equation usually takes on a linear form since the coefficients of the higher-order variables (a2, a3, etc.) are relatively small.

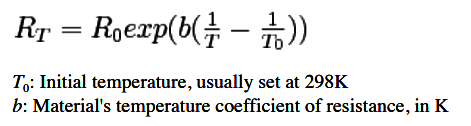

Another type of RTD is the thermistor, which operates based upon an exponential relationship between electrical resistance and temperature. Thermistors are primarily composed of semiconductors, and are usually used as fuses, or current-limiting devices. Thermistors have high thermal sensitivity but low temperature measuring ranges and are extremely non-linear. Instead of the Callendar - Van Dusen equation, the thermistor operates based upon the nonlinear equation, equation (2), shown in degrees K.

Errors associated with resistance thermometers will occur due to the individual or collective efforts of: defective insulation, contamination of the resistor, or insecure lead wire connections.