Working Principle of Thermowell

Thermowell provide protection for temperature probes against unfavorable operating conditions such as corrosive media, physical impact (e.g. clinker in furnaces) and high pressure gas or liquid. Their use also permits quick and easy probe interchanging without the need to open-up the process.

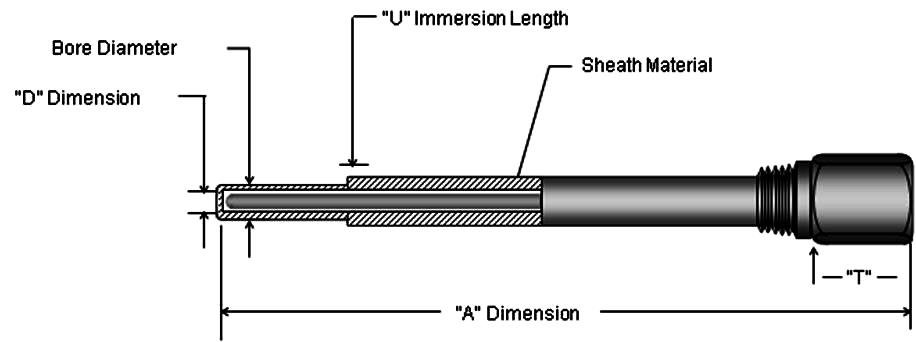

It is closed-end reentrant tube designed for insertion of a temperature-sensing element, and provided with means for a pressure-tight attachment to a vessel.

Thermowells are typically constructed of solid drilled-out bar stock and are designed to protect a temperature sensors from flow, high pressure and harsh environment.

Working:

- Thermowells are hidden in pipes and are rarely seen. Thermowells are permanently placed into pipes, tanks or sumps so that temperature measurement probes can be inserted into the pipe to measure the contents temperature.

- Welding and brazing is important for the installation requiring seal. The pipe thread provides mechanical strength, and the weld or braze provides the seal.

- Installing temperature sensor assembles into thermowell or directly into the process requires the use of some kind of brass or stainless steel fitting. Fitting include various threaded unions, bayonet cap (and adapters) and flange.

- Adjustable compression fitting are used directly on probe to achieve the required insertion length in the process and to ensure the proper sheathing of probes into thermowell.